LogoTurtle

A programmable floor turtle

With Brian Silverman and Erik

Nauman, we adapted an Instructable Arduino floor turtle robot to run

Brian's LogoTurtle.

These instructions will teach you

how to construct and begin programming your own LogoTurtle robot.

"The idea of mucking about in

programming is, for better or for worse, not very popular in grown up

computer science. Programming these days has become more of an

engineering discipline with the idea being that you should do things

once and do it right. Logo is and always was about debugging. Before

the do it right stage there are always dozens if not hundreds of do it

not-quite-right stages. This iterate-iterate-iterate then iterate again

is not very prevalent in work with microcontrollers. LightLogo and

TurtleLogo try to make microcontroller programming interactive but they

are far from the mainstream."

Brian Silverman

3D Printing and Assembly

3D print the models at .3mm layer

height, 2 shells, 25% infill, with

the exception of the chassis, which should be 3D printed at 35% infill.

Insert the 5/8" ball

bearing as soon as the 3D printer stops

for an easy, perfect fit. The ball may not rotate when the turtle is

moving but that is fine.

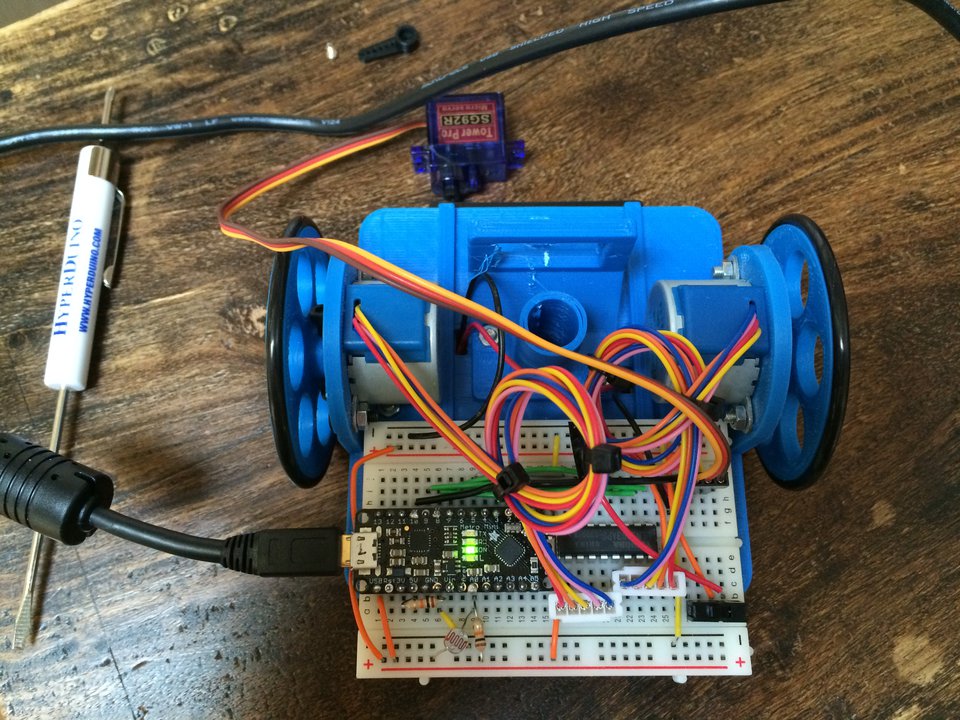

This variation of the robot uses a

different microcontroller than the

original version. Please follow steps 3 through 6 in the original

instructions to assemble the 3D printed parts and attach the

stepper motors.

Consider using a small piece of

wood to shim between the 3D printed stepper motor mounts. This reduces

the amount of bowing in the chassis and helps keep the wheel base

measurement consistent across turtles. When you calibrate your turtle

later, you can get the turtle to turn almost perfectly 90 degrees by

finding the correct length of shim that the robot needs.

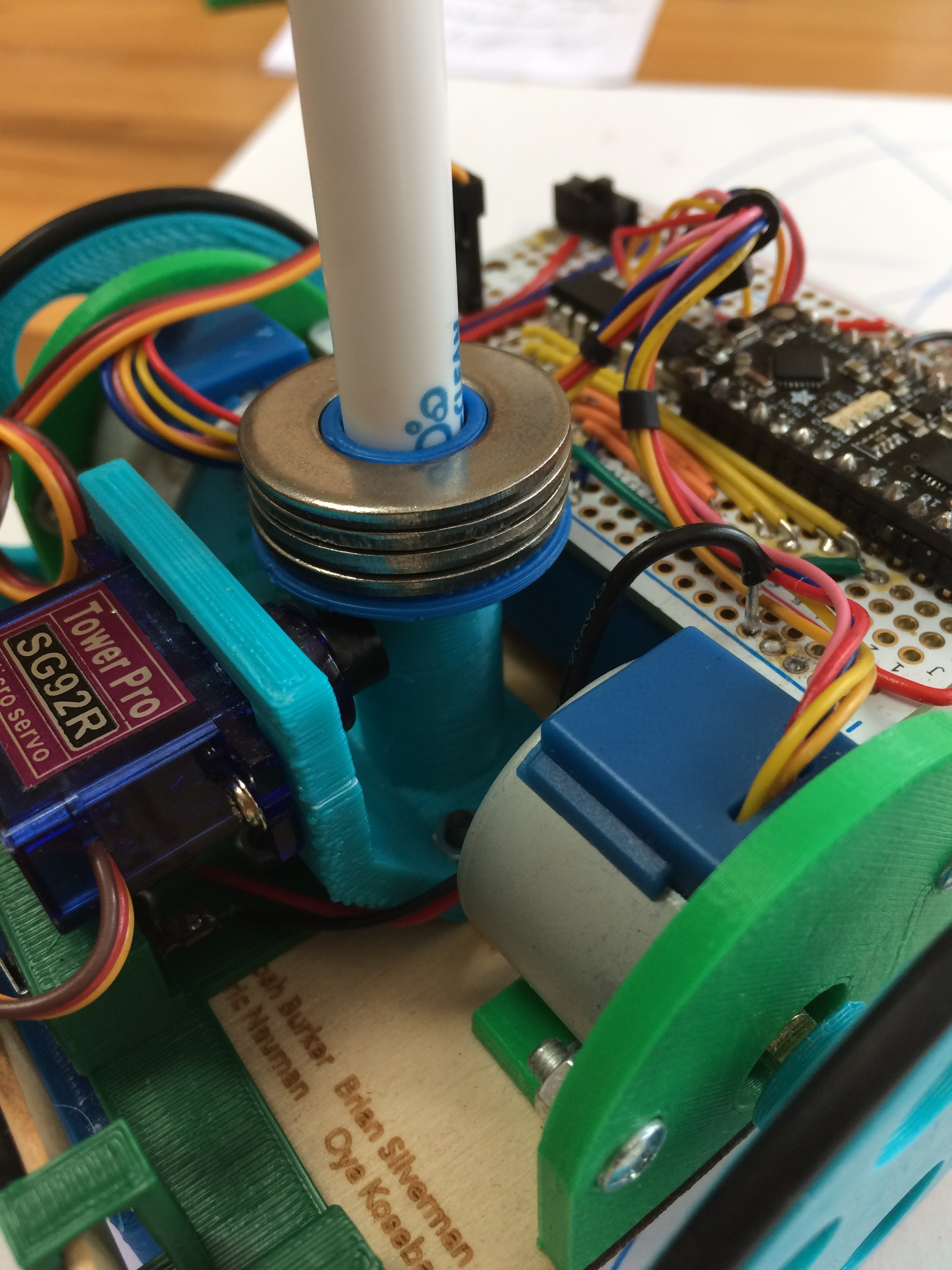

Remove the 3D printed pen

holder/servo bracket so you have access to the complete underside of

the turtle before you build the electronics.

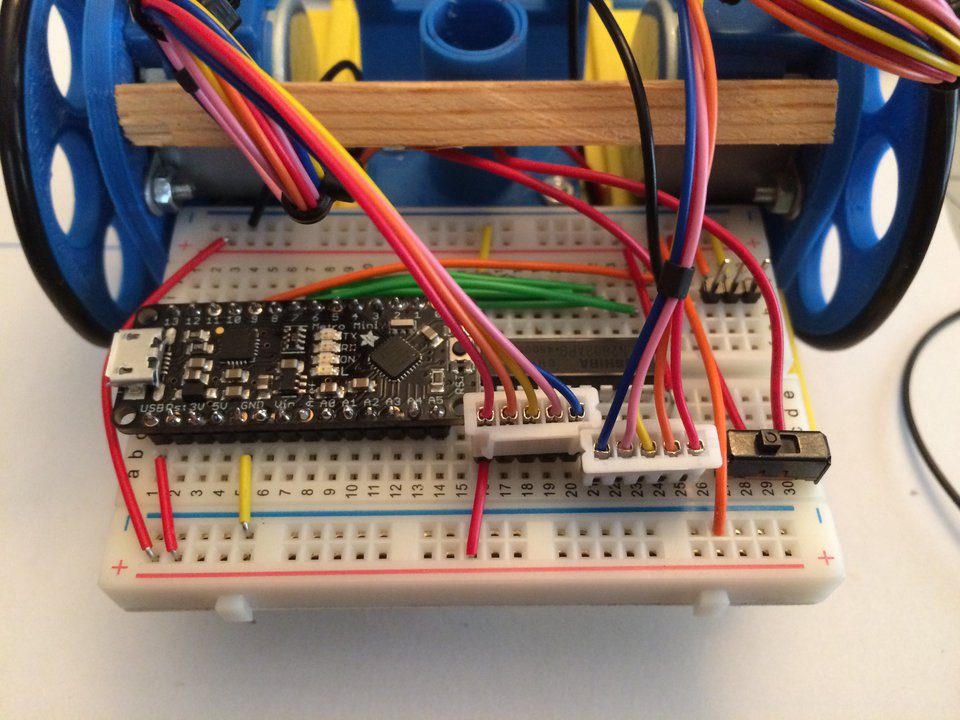

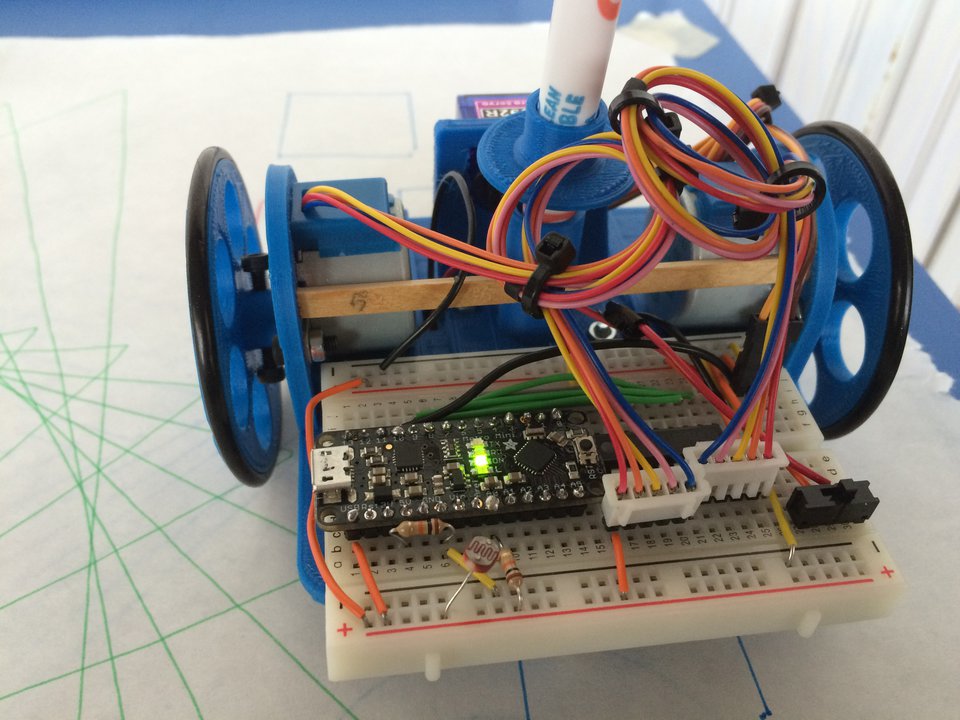

The turtle's electronics are built

around the affordable Adafruit Metro Mini microcontroller.

Additionally, please purchase the

following parts:

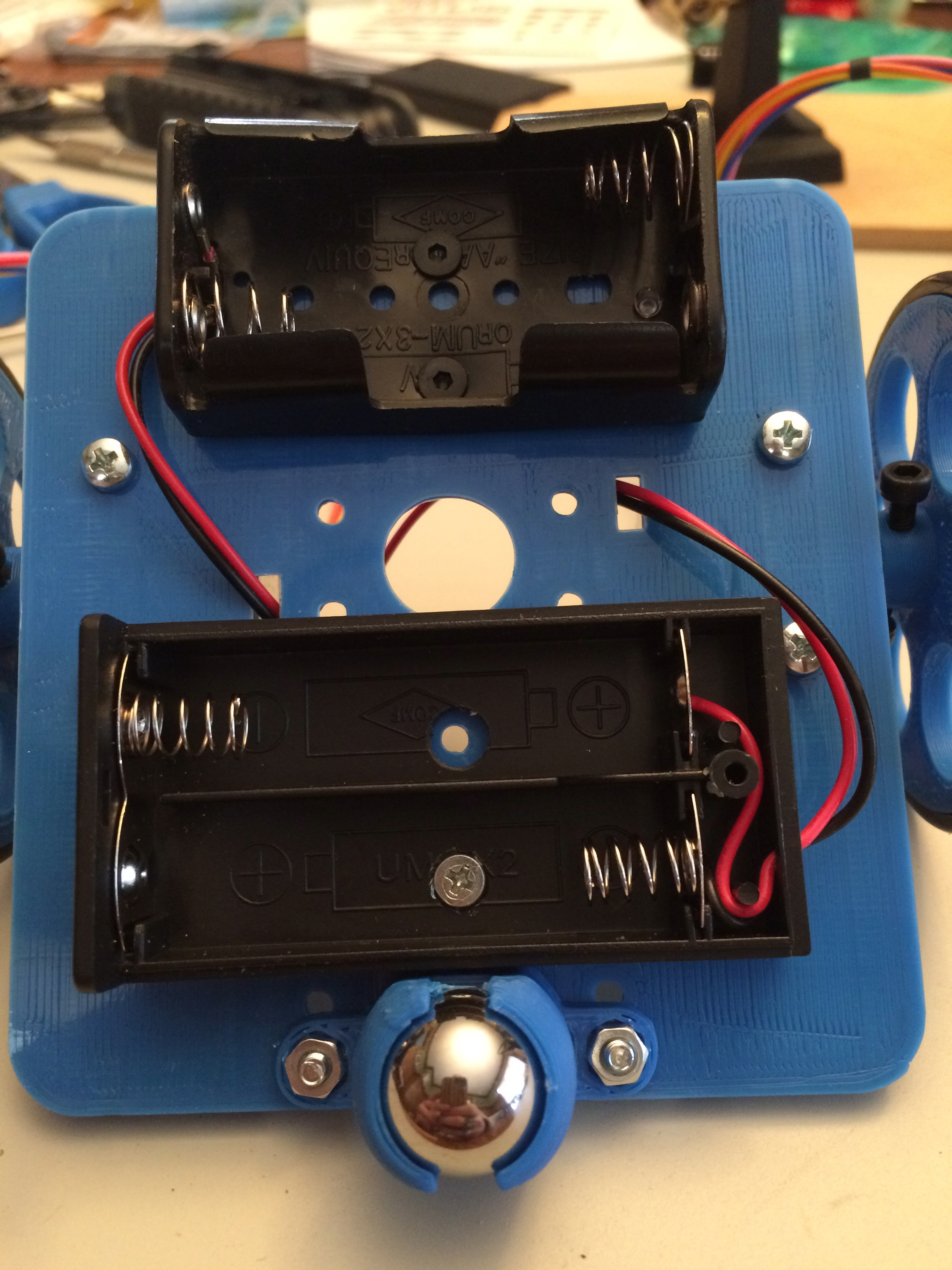

Attach the battery holders

according to the Instructable directions.

Once the battery holders are

attached, route the wires through the slots on the underside of the

turtle.

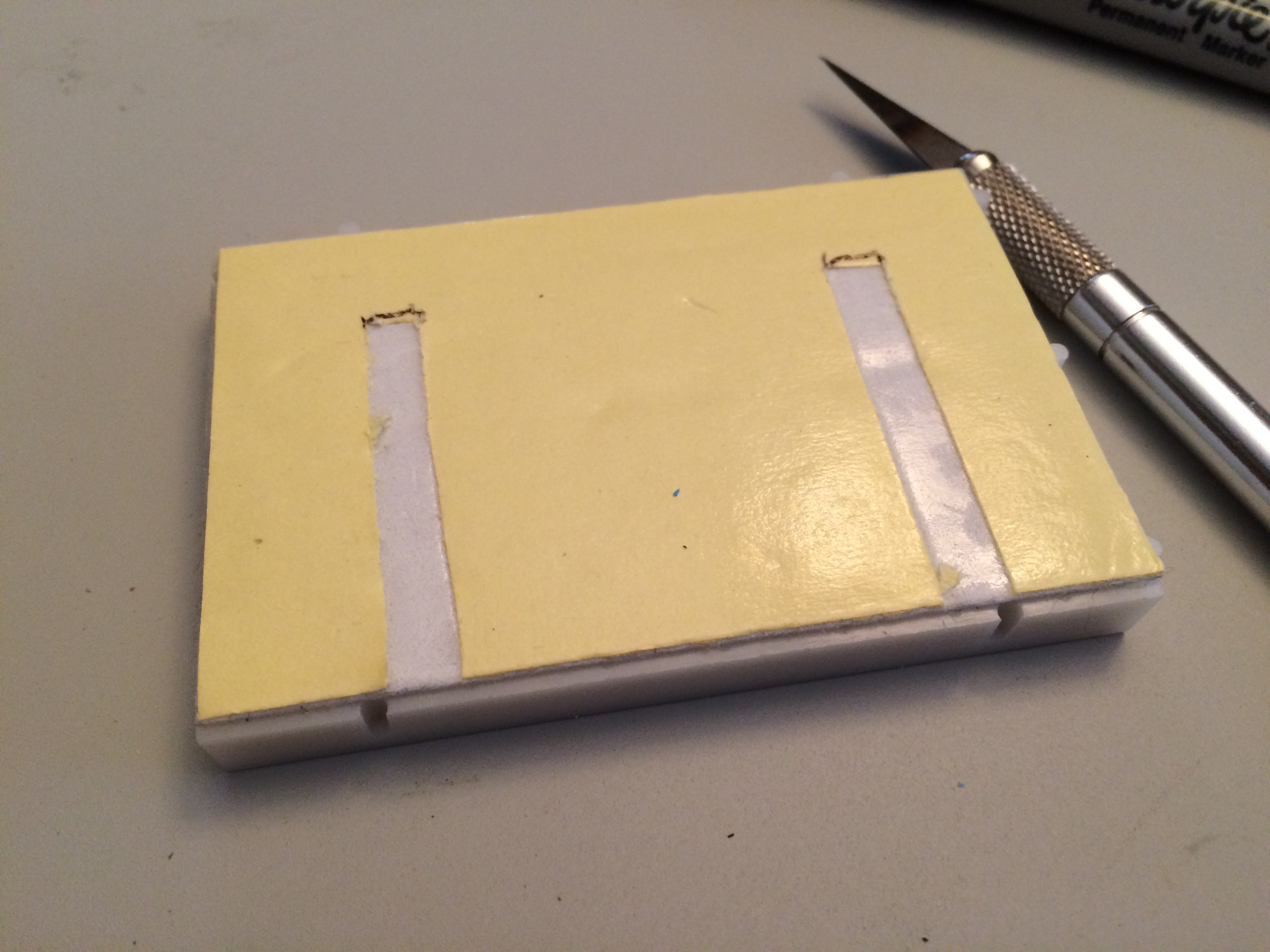

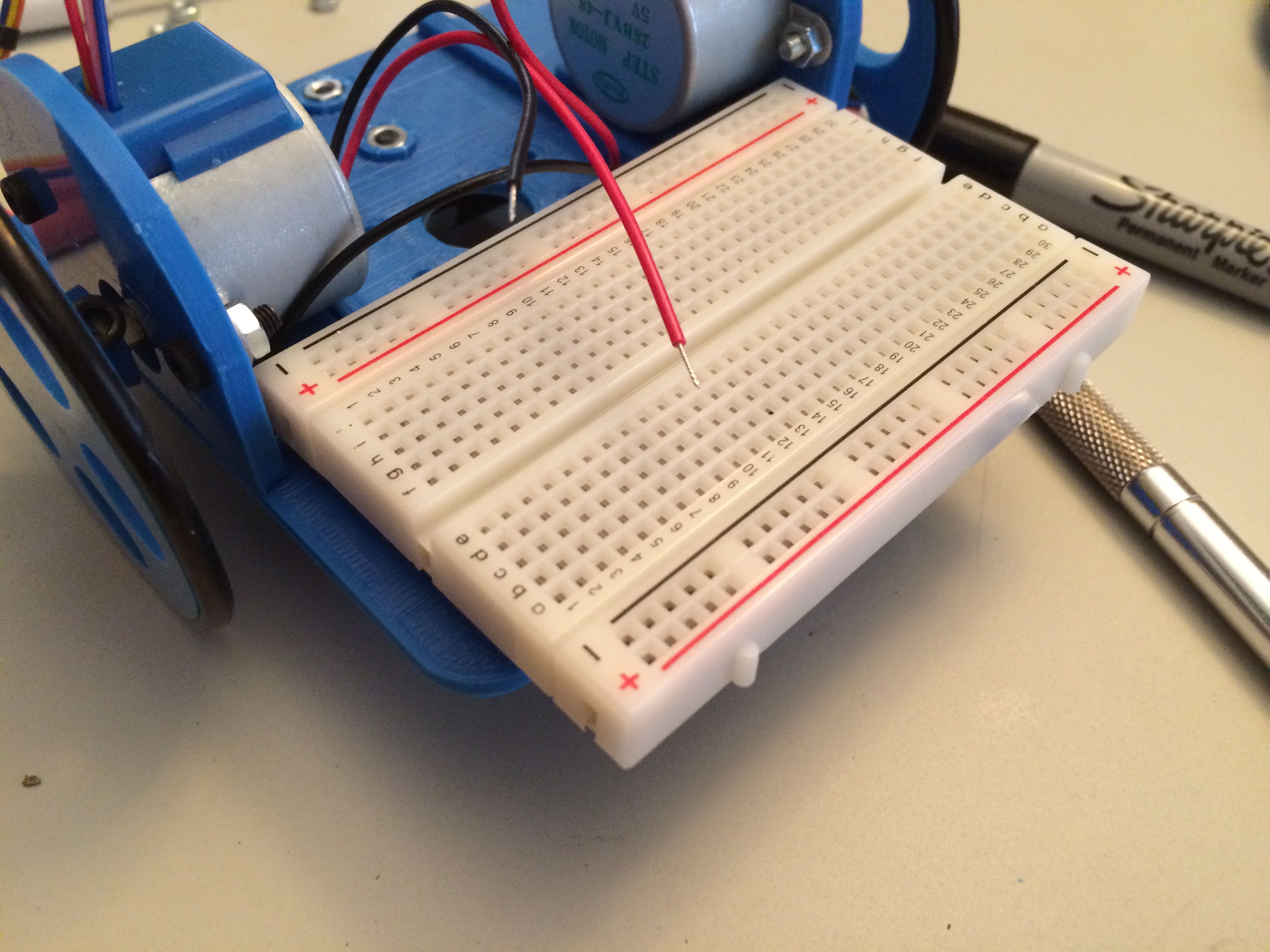

Using the rails on the top of the

chassis as a guide, use a knife to score the backing on the breadboard

without cutting the adhesive underneath. Remove the backing and attach

the breadboard to the top side of the chassis. Orient the breadboard so

the higher numbers are towards the right side. The breadboard will hang

out over the rear of the turtle.

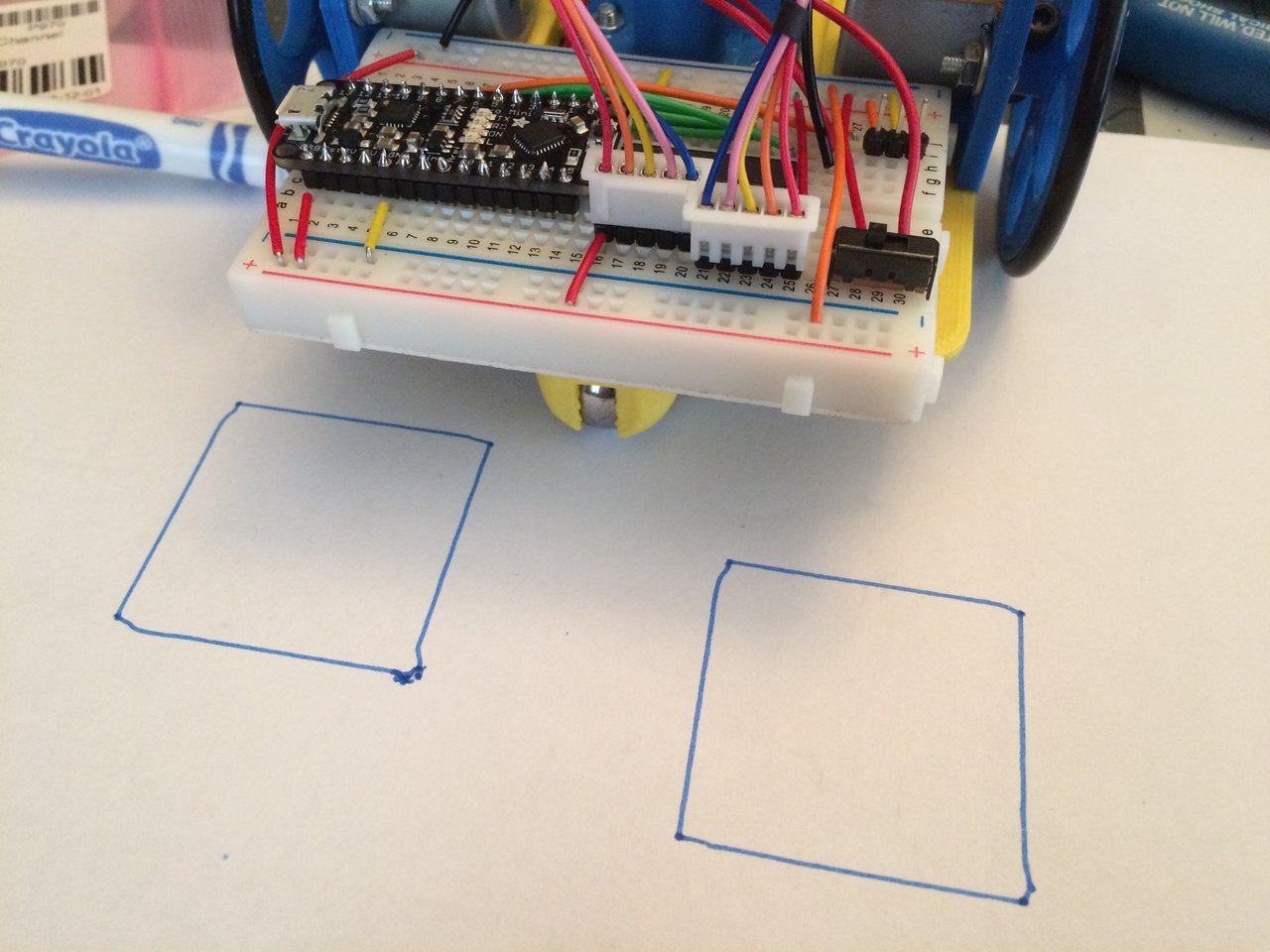

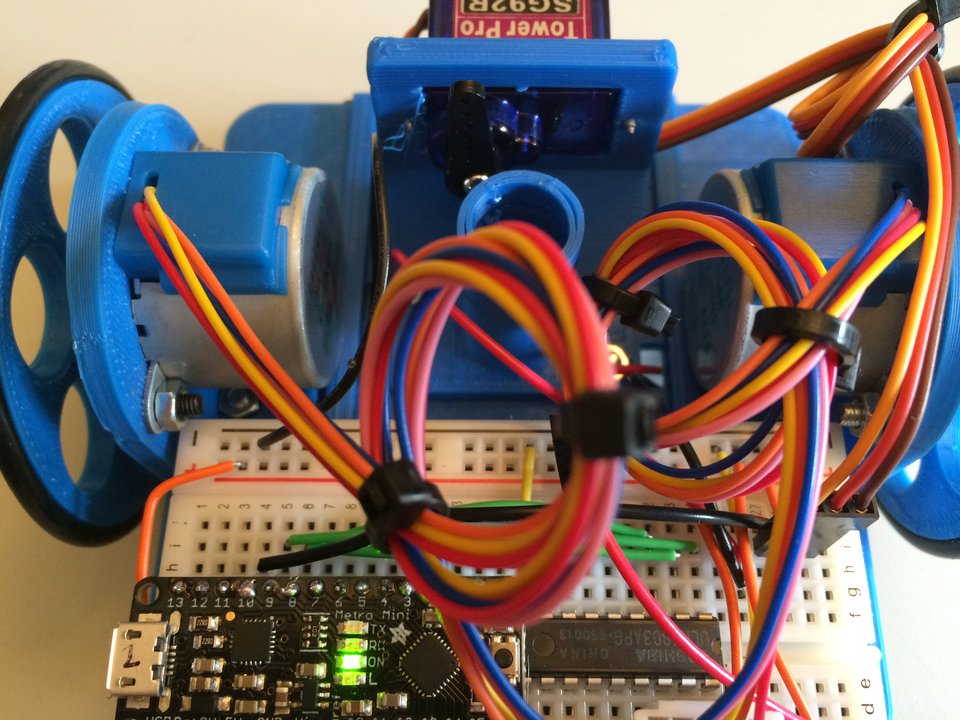

Building the Electronics

If you have never used a breadboard to assemble a circuit, please see this tutorial to familiarize yourself.

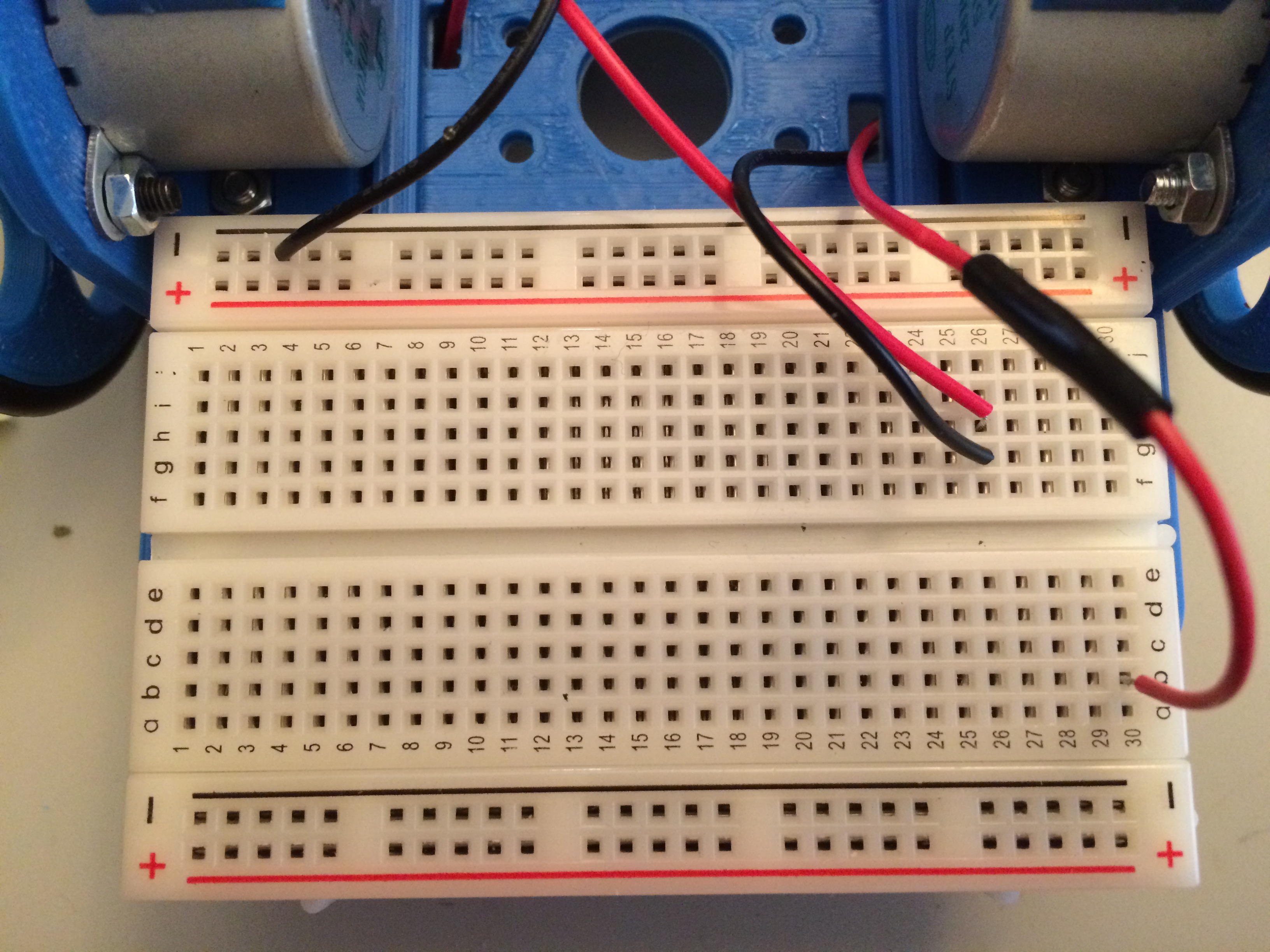

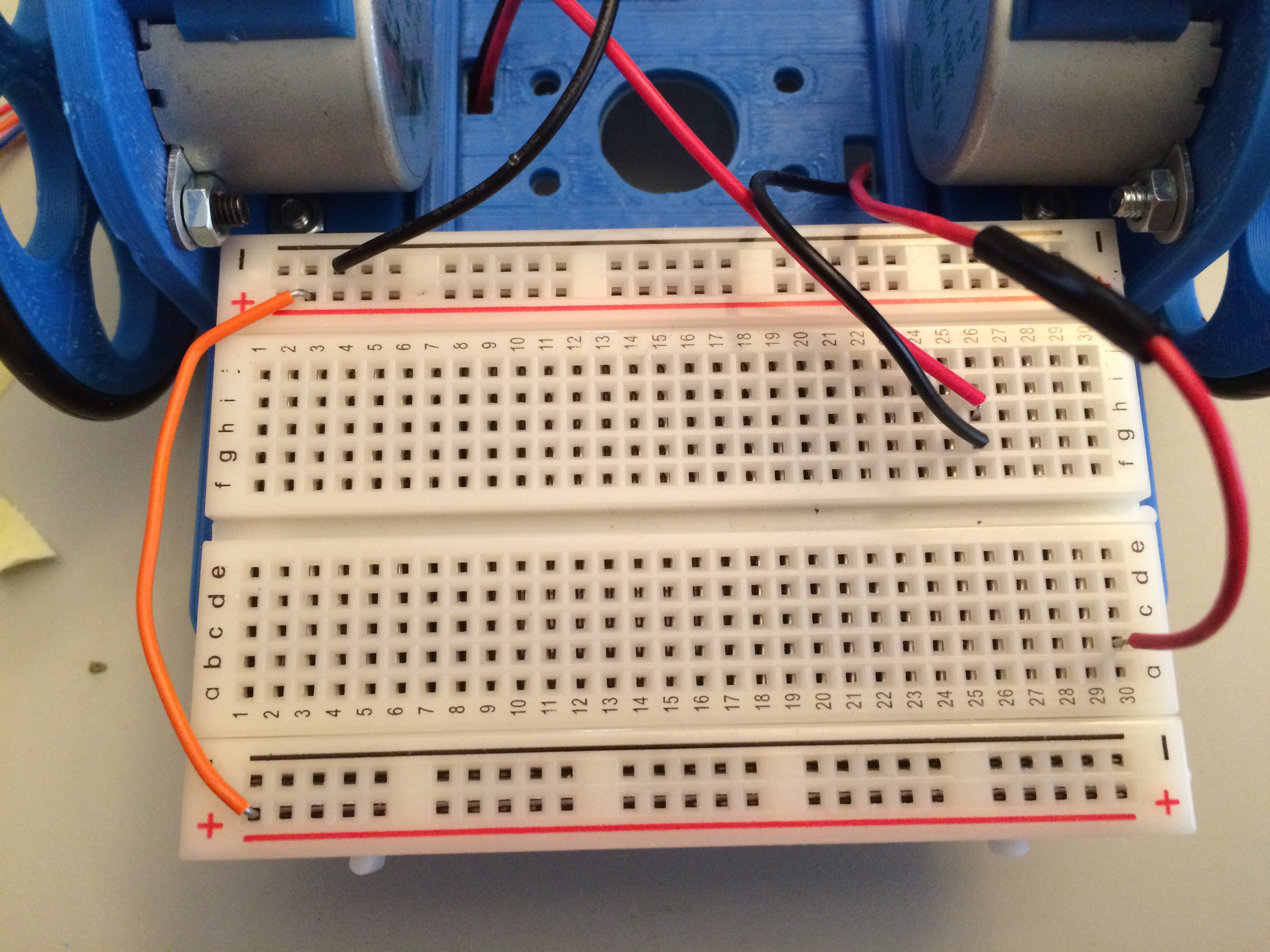

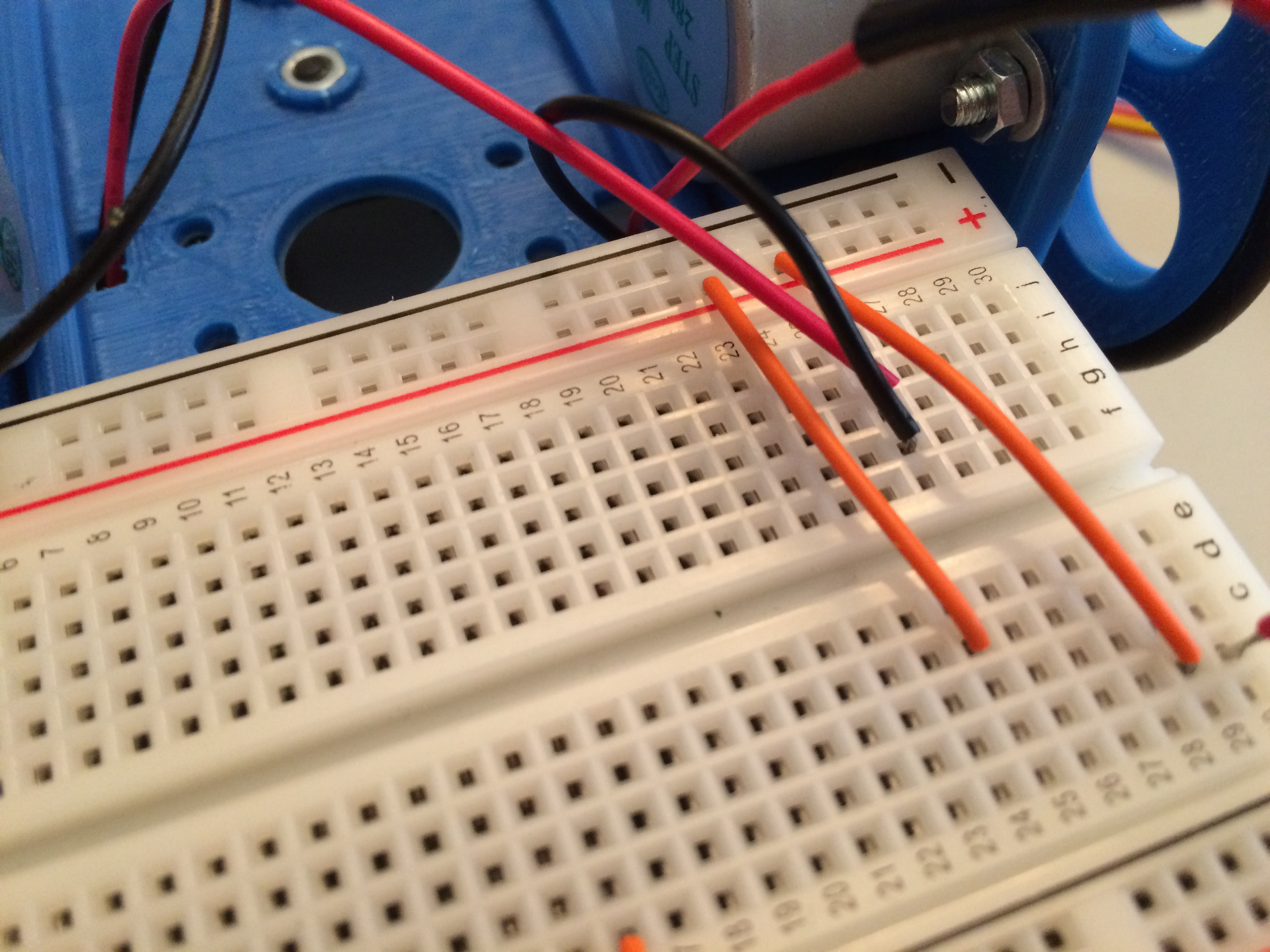

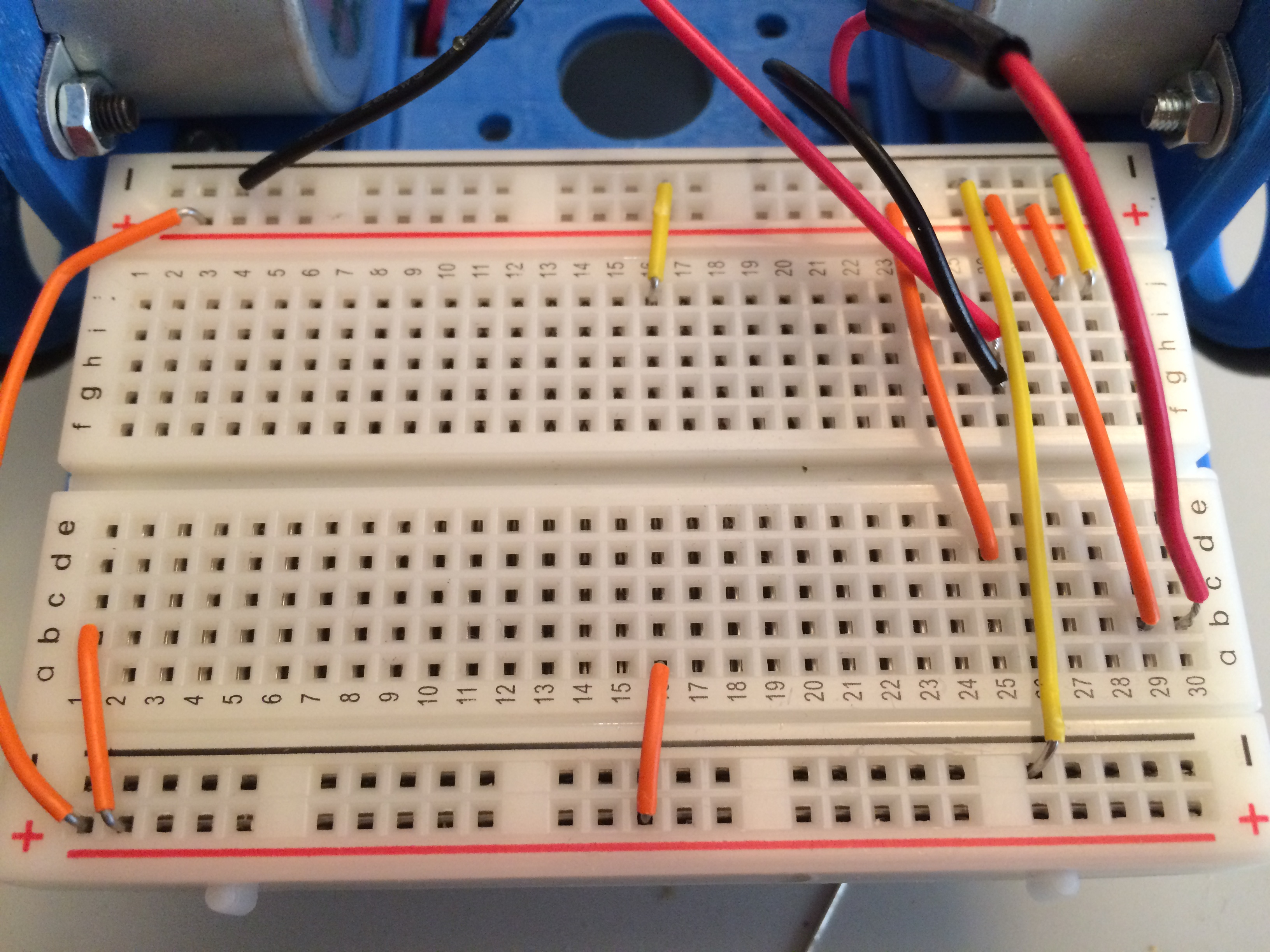

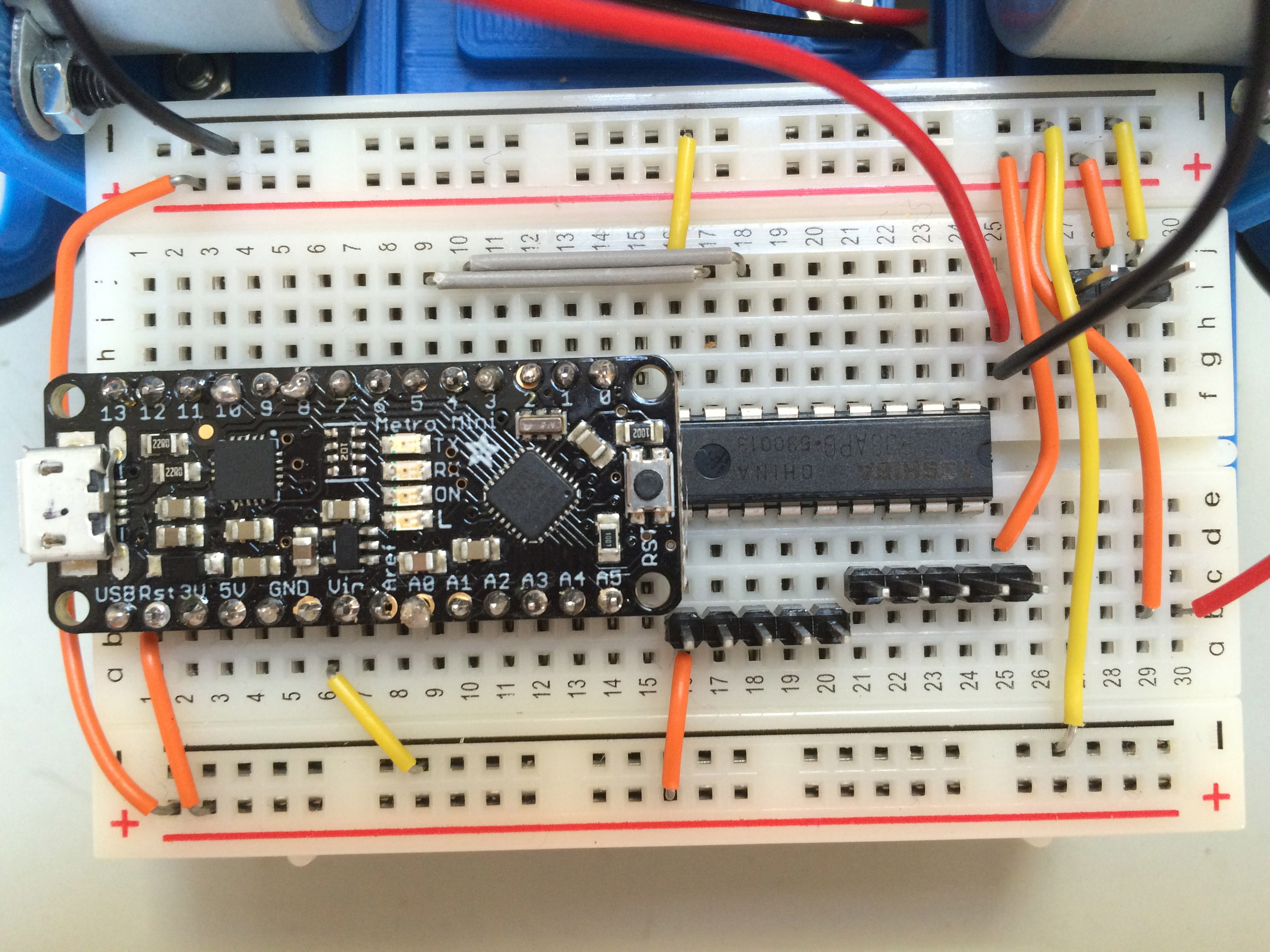

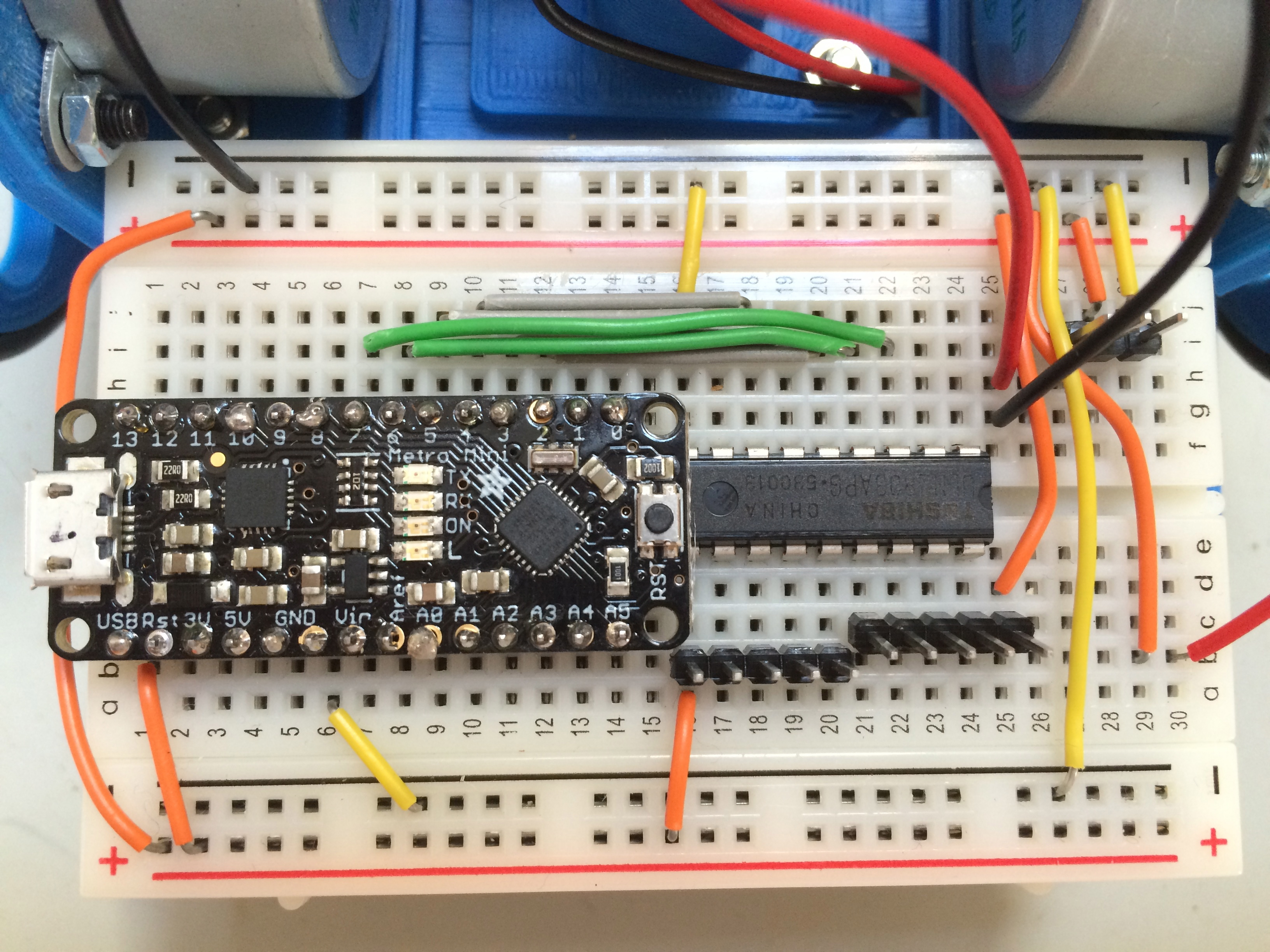

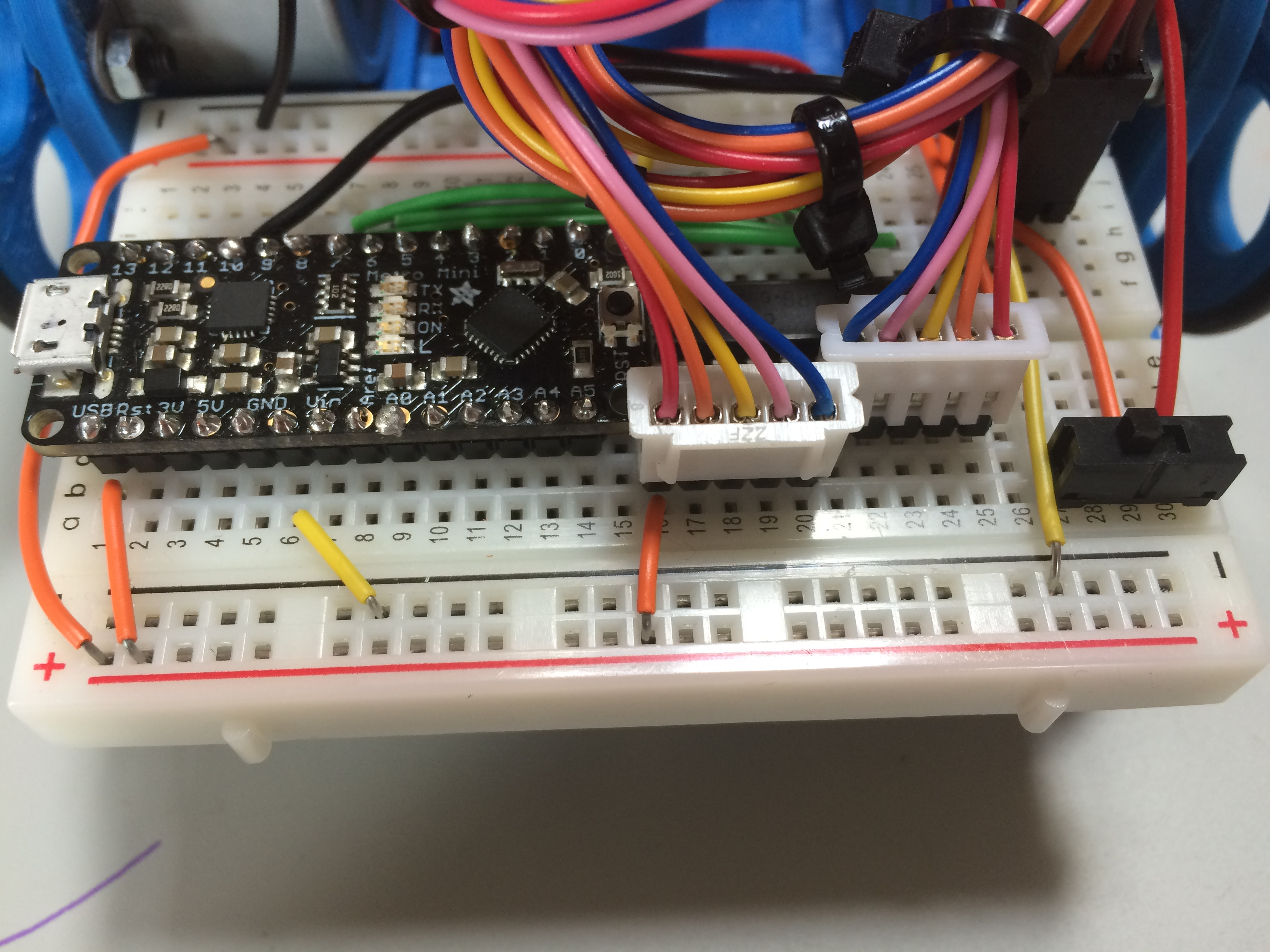

With your turtle oriented as shown

in the image above, plug the black negative lead from the left battery

holder into hole 3 on the rear negative rail. The red positive lead

from that battery holder plugs into hole h26 on the breadboard.

The black negative lead from the

right battery holder plugs into hole g26 on the breadboard. The red

positive lead from that battery holder plugs into hole b30 on the

breadboard.

Choose a color of jumper wire to

use for the rest of the positive wiring on the breadboard. I chose

orange.

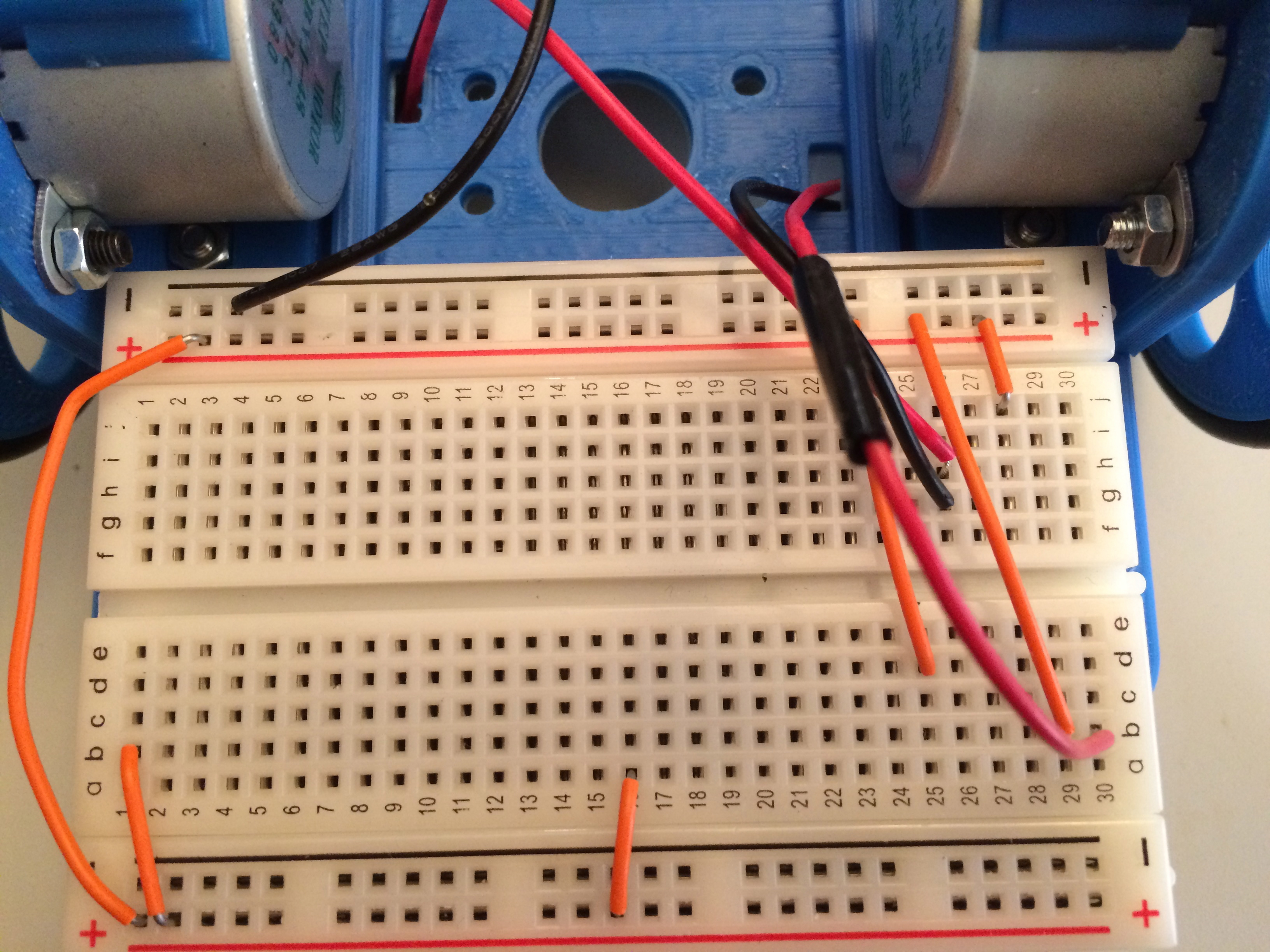

Connect a jumper wire from the

second hole on the far positive rail to the first hole on the positive

rail closest to you.

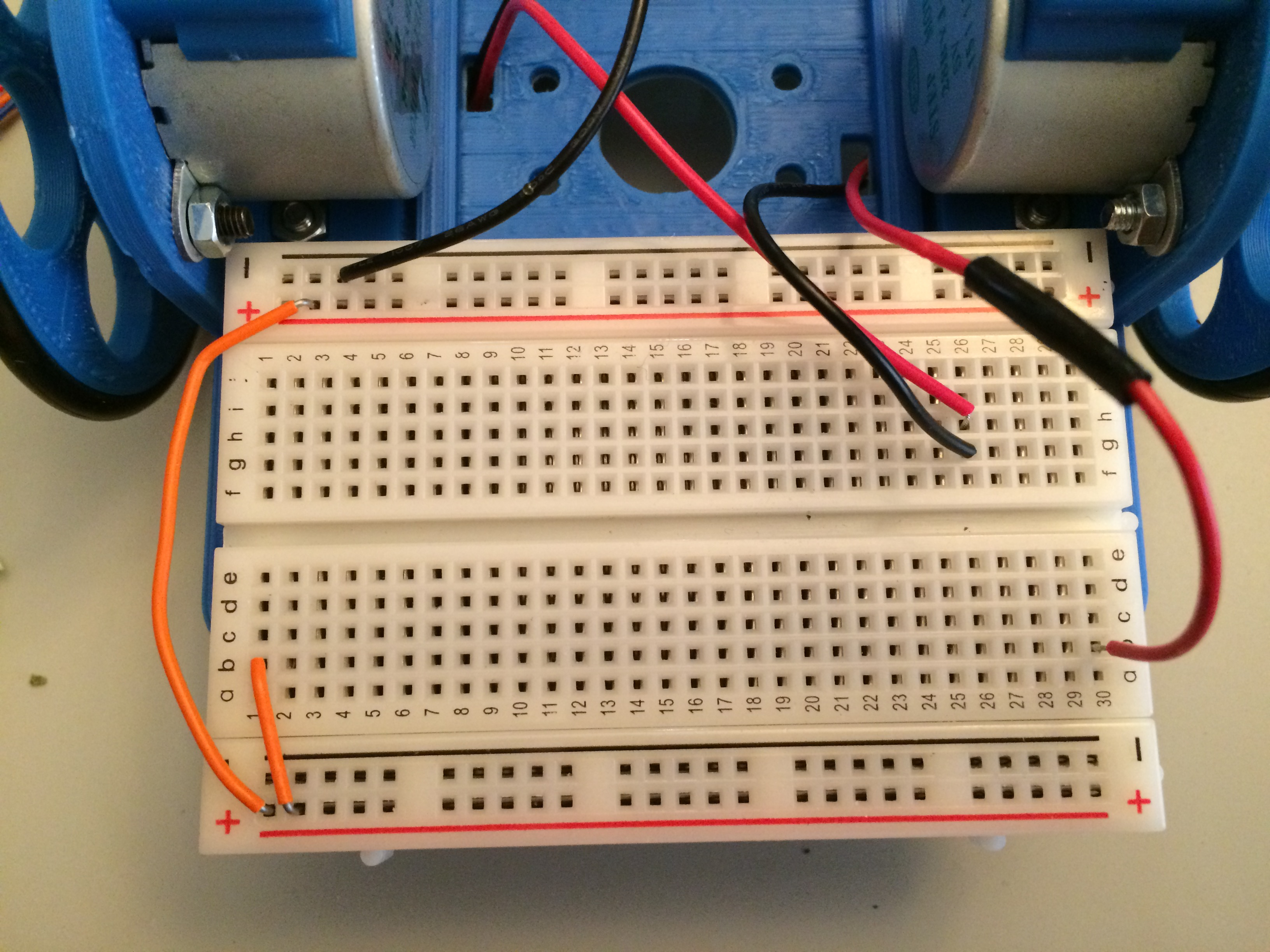

Connect a short jumper wire from

the second hole on the close positive rail to hole b1 on the breadboard.

Connect a short jumper wire from

hole 13 on the close positive rail to hole a16 on the breadboard.

Connect a jumper wire from hole 27

on the far positive rail to hole b29 on the breadboard. (The photo

shows hole 26 on the rail, but the jumper wire should be connected to

hole 27 on the positive rail).

Connect a jumper wire from hole 25

on the far positive rail to hole d25 on the breadboard.

The final positive connection is

from the far positive rail hole 28 to hole j28 on the breadboard.

You have now completed the positive

wiring, excluding the power switch.

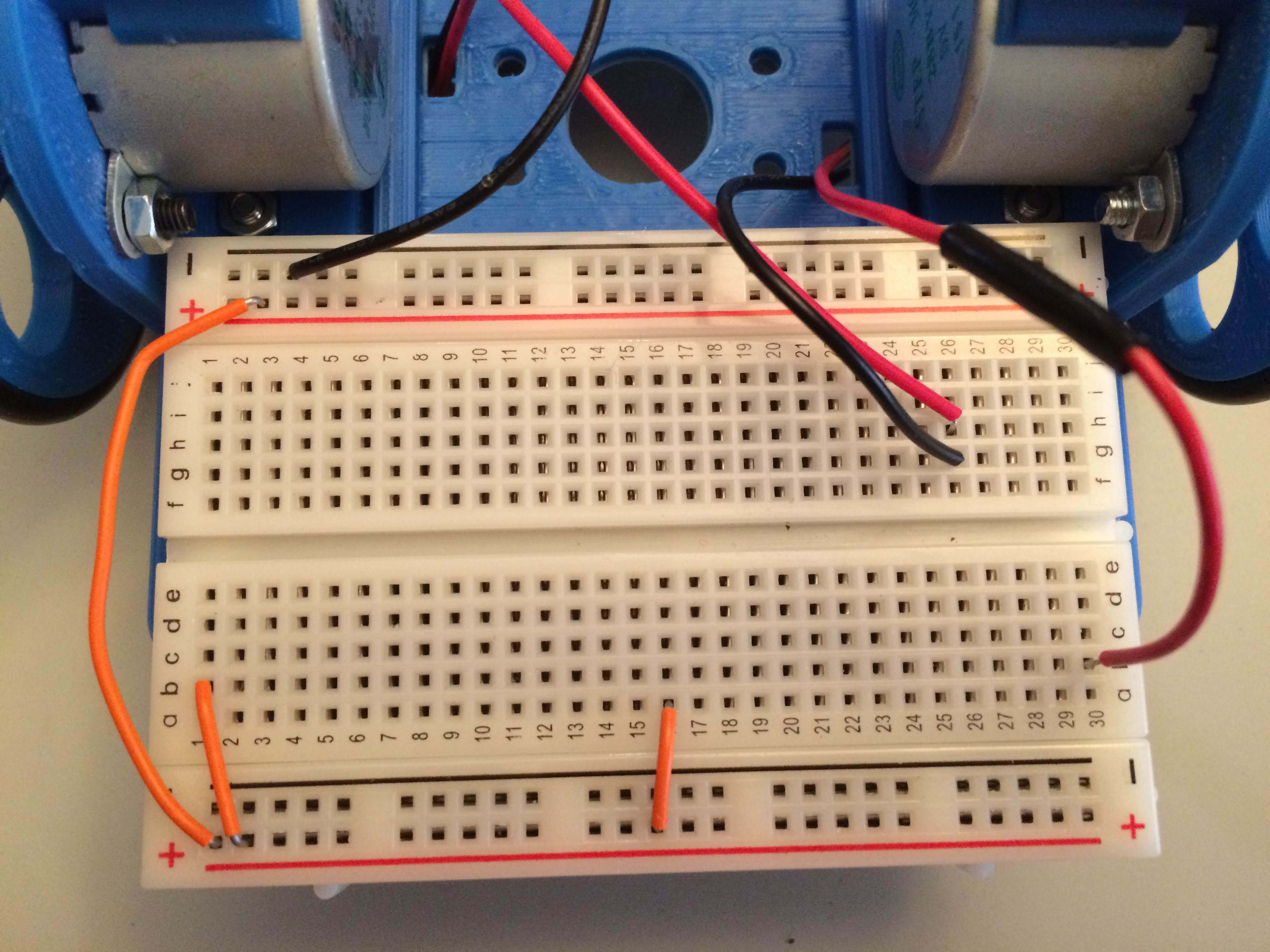

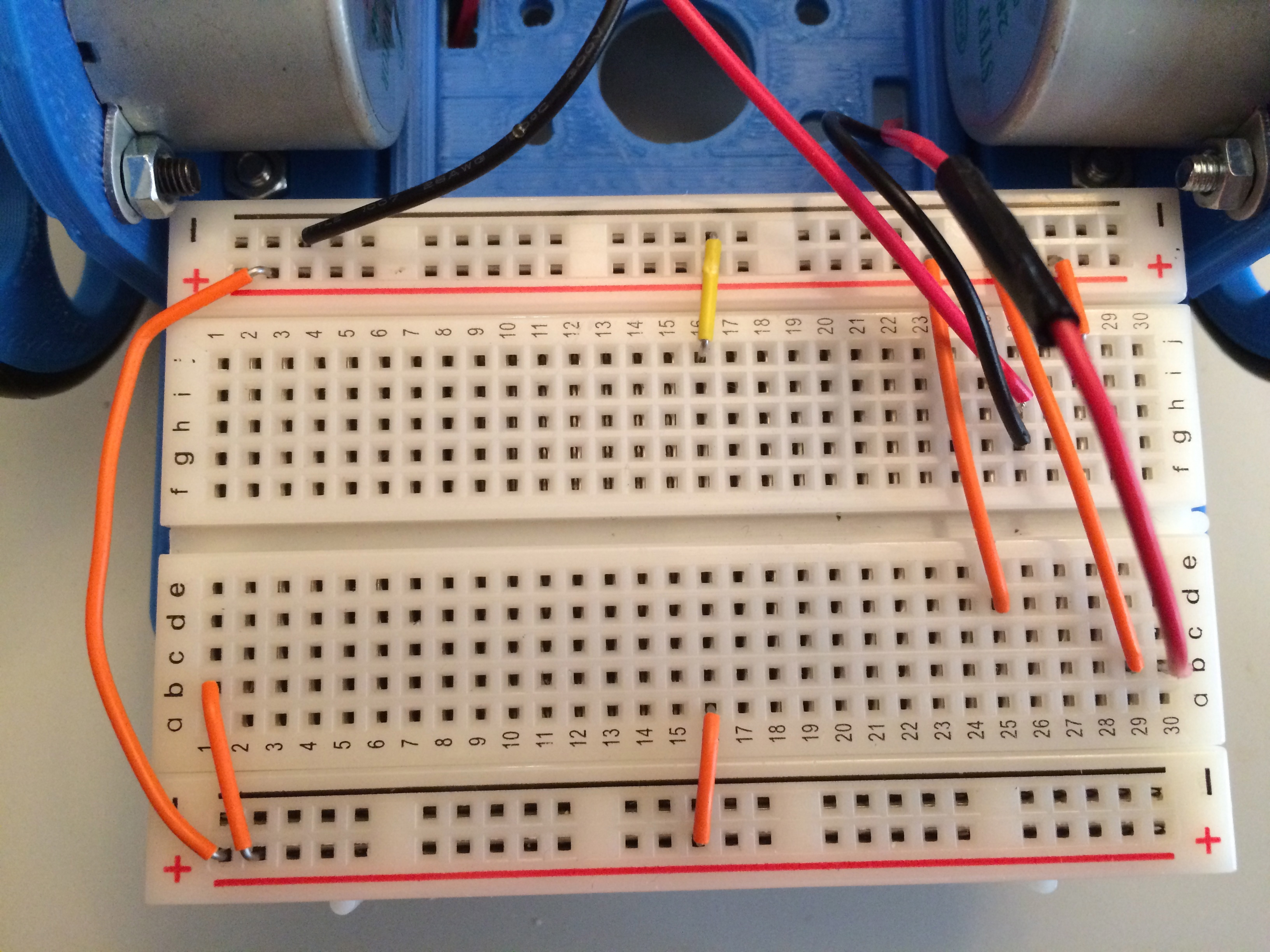

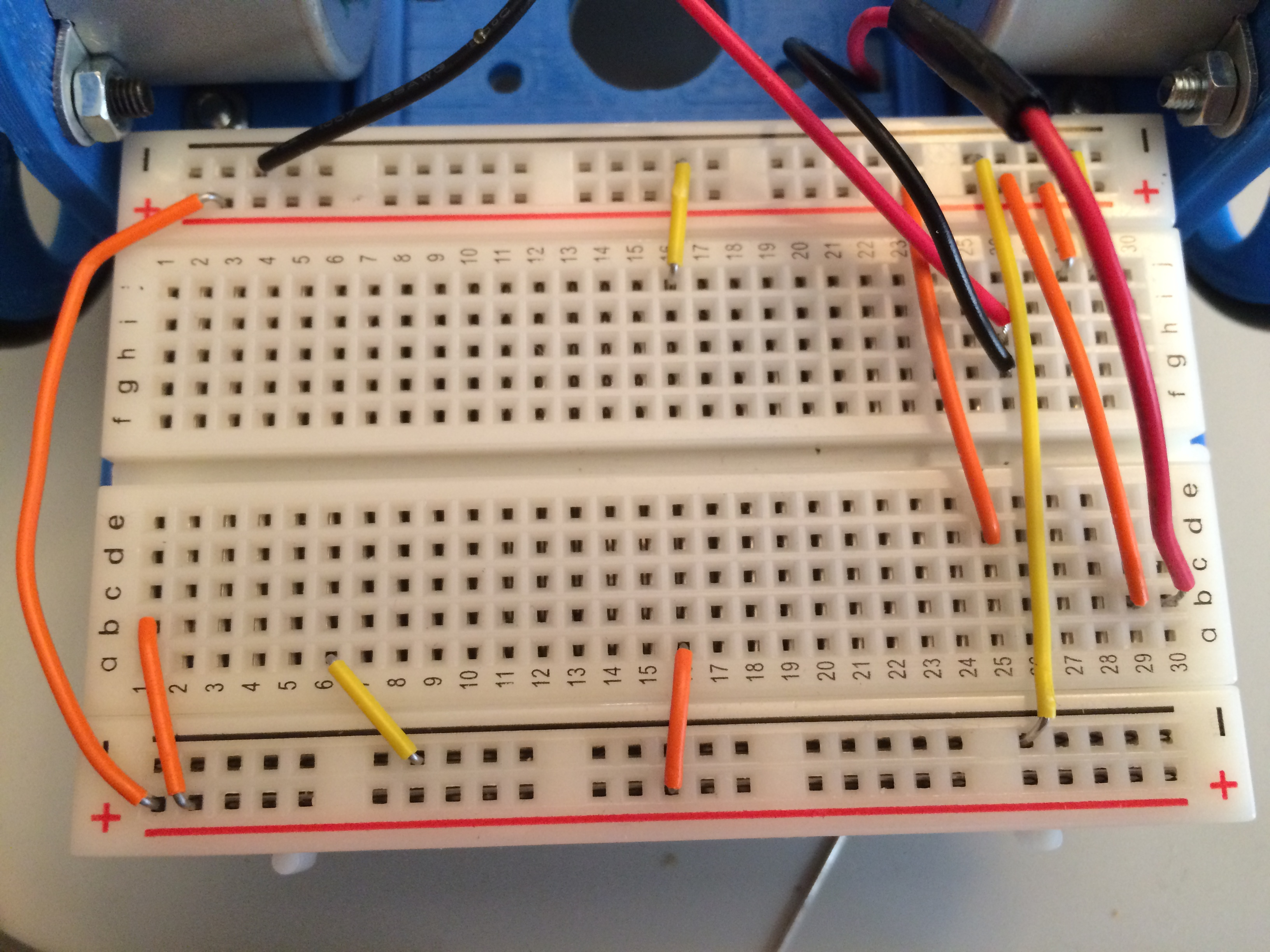

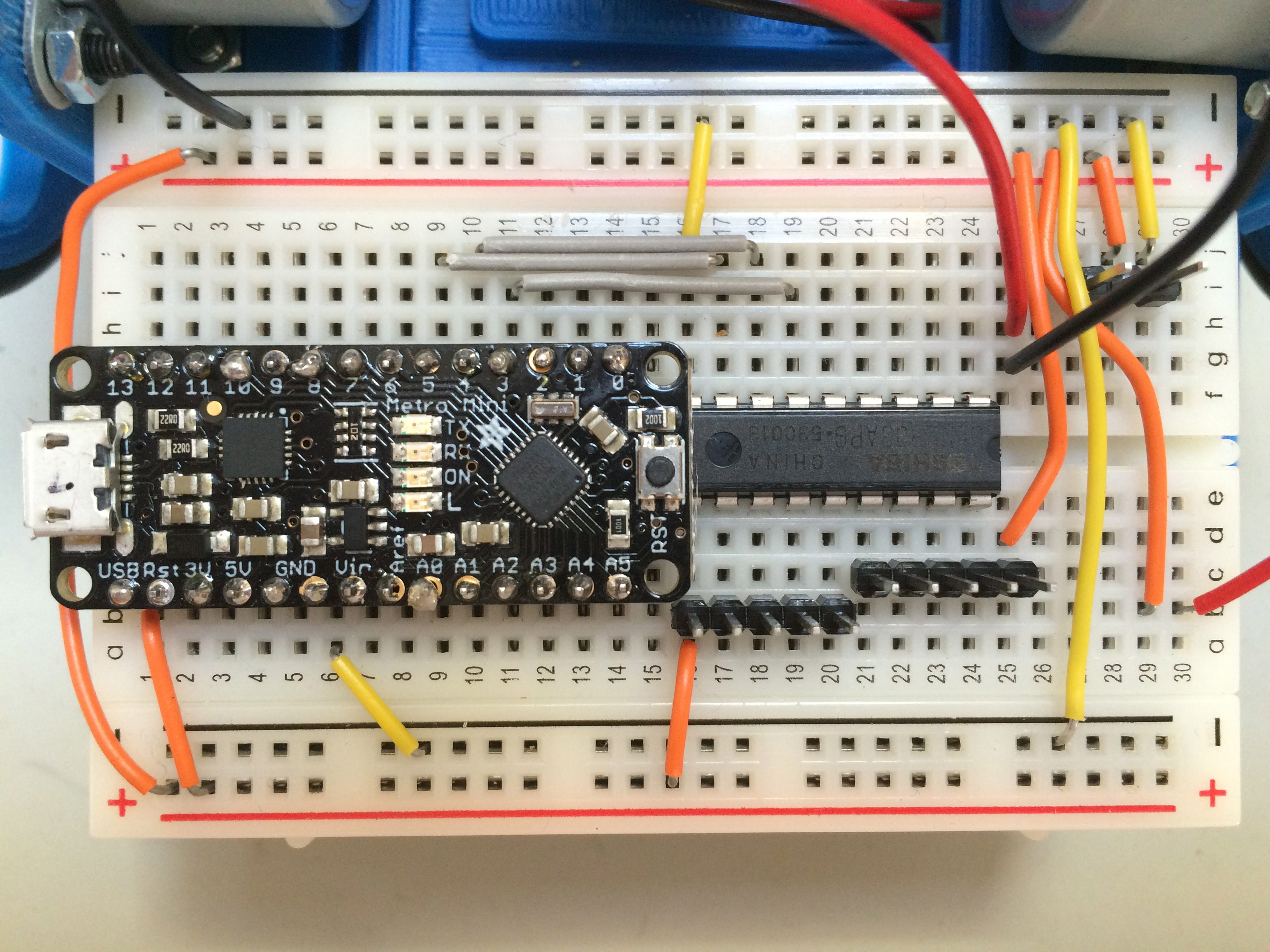

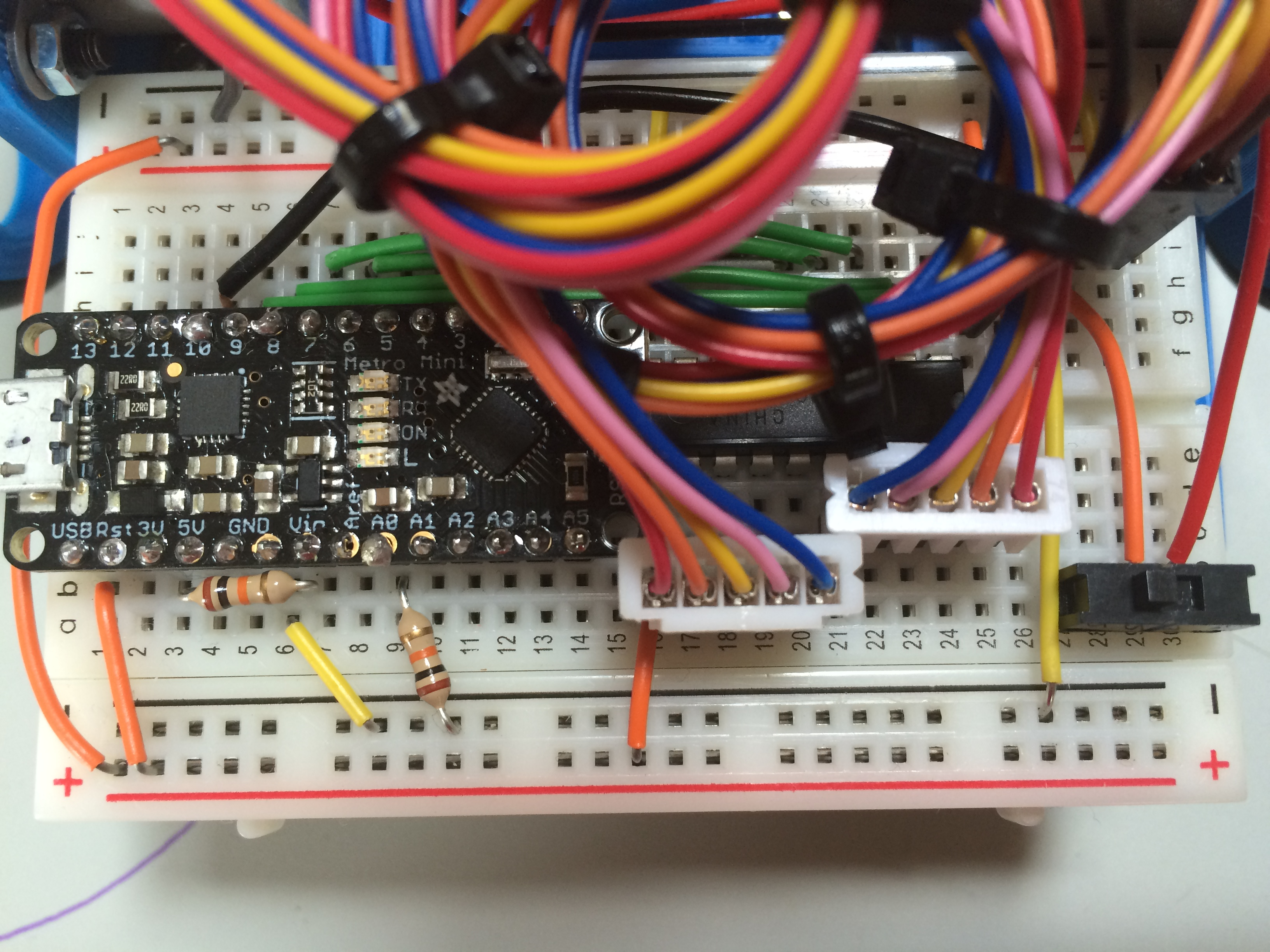

Now you will wire the negative

leads on the breadboard.

Choose a different color jumper

wire for your negative connections. I chose yellow.

Start with a small jumper wire

between the far negative rail hole 14 to hole j16 on the breadboard.

Next, connect a short jumper wire

from hole 29 on the far negative rail to hole j29 on the breadboard.

Connect a jumper from the far

negative rail hole 26 to the near negative rail hole 26.

Connect a short jumper from hole 7

on the near negative rail to hole a6 on the breadboard.

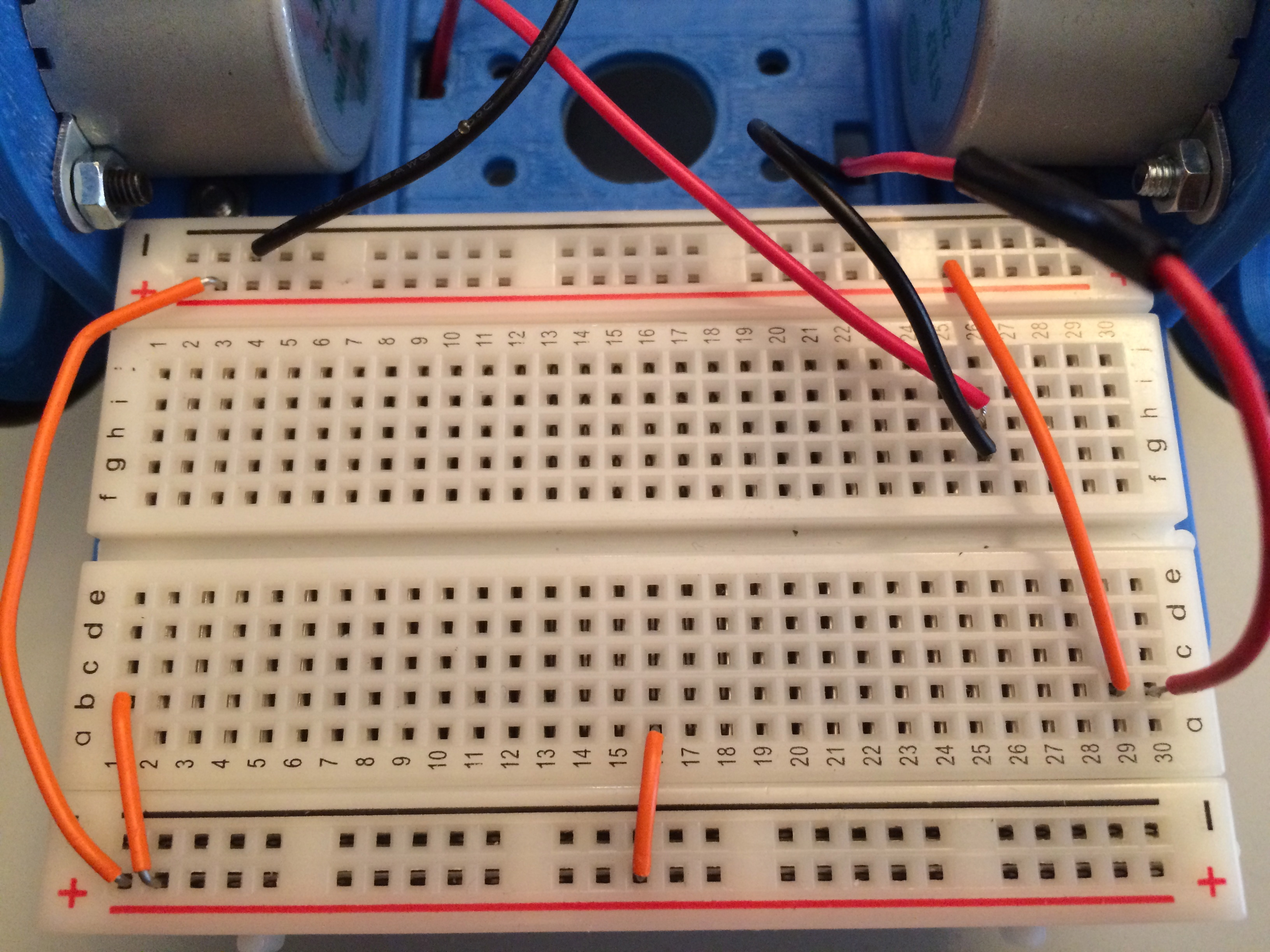

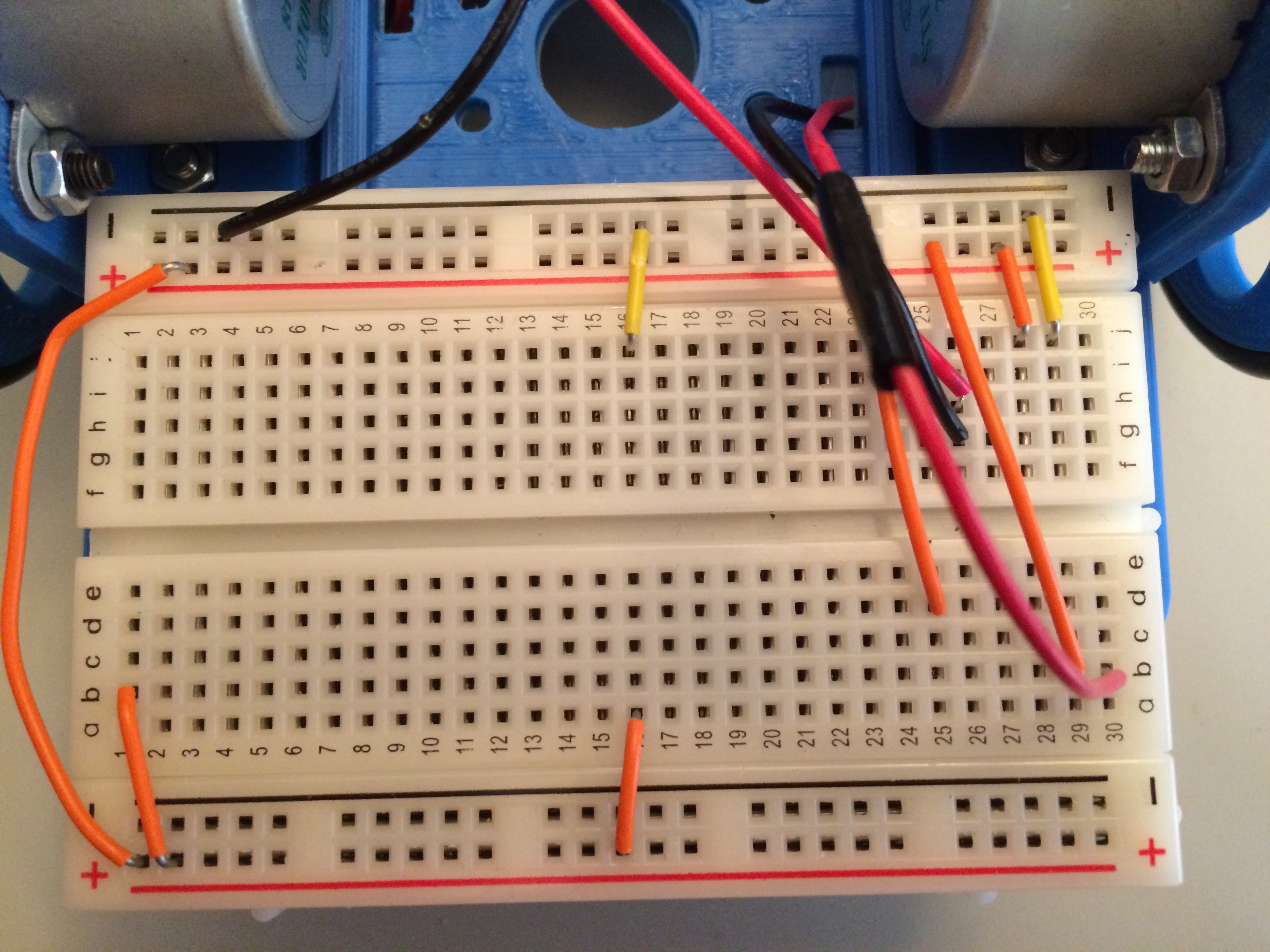

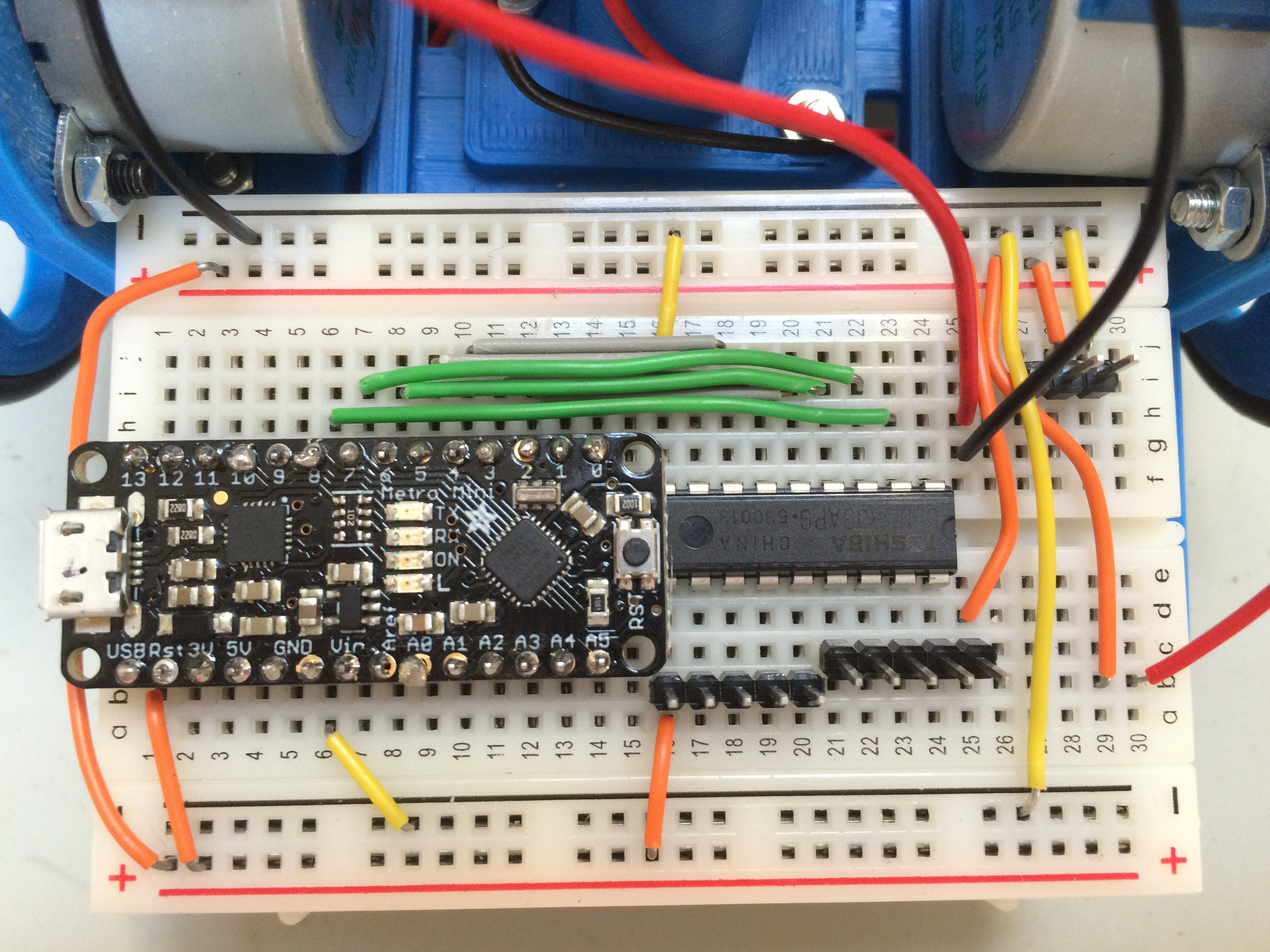

Insert header pins into the

breadboard from b16-20 and c21-25.

Insert three header pins in holes

i27-29 on the breadboard.

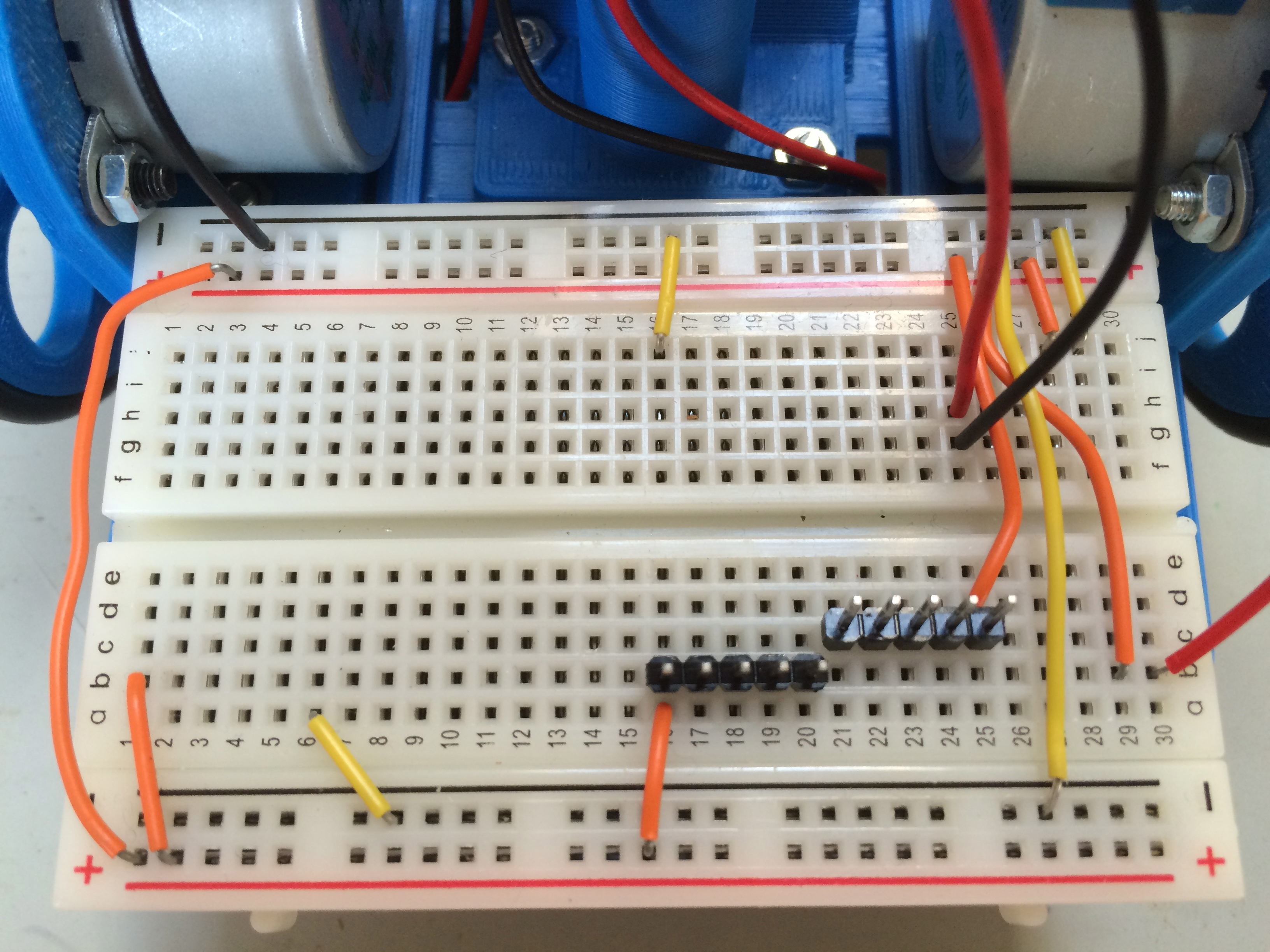

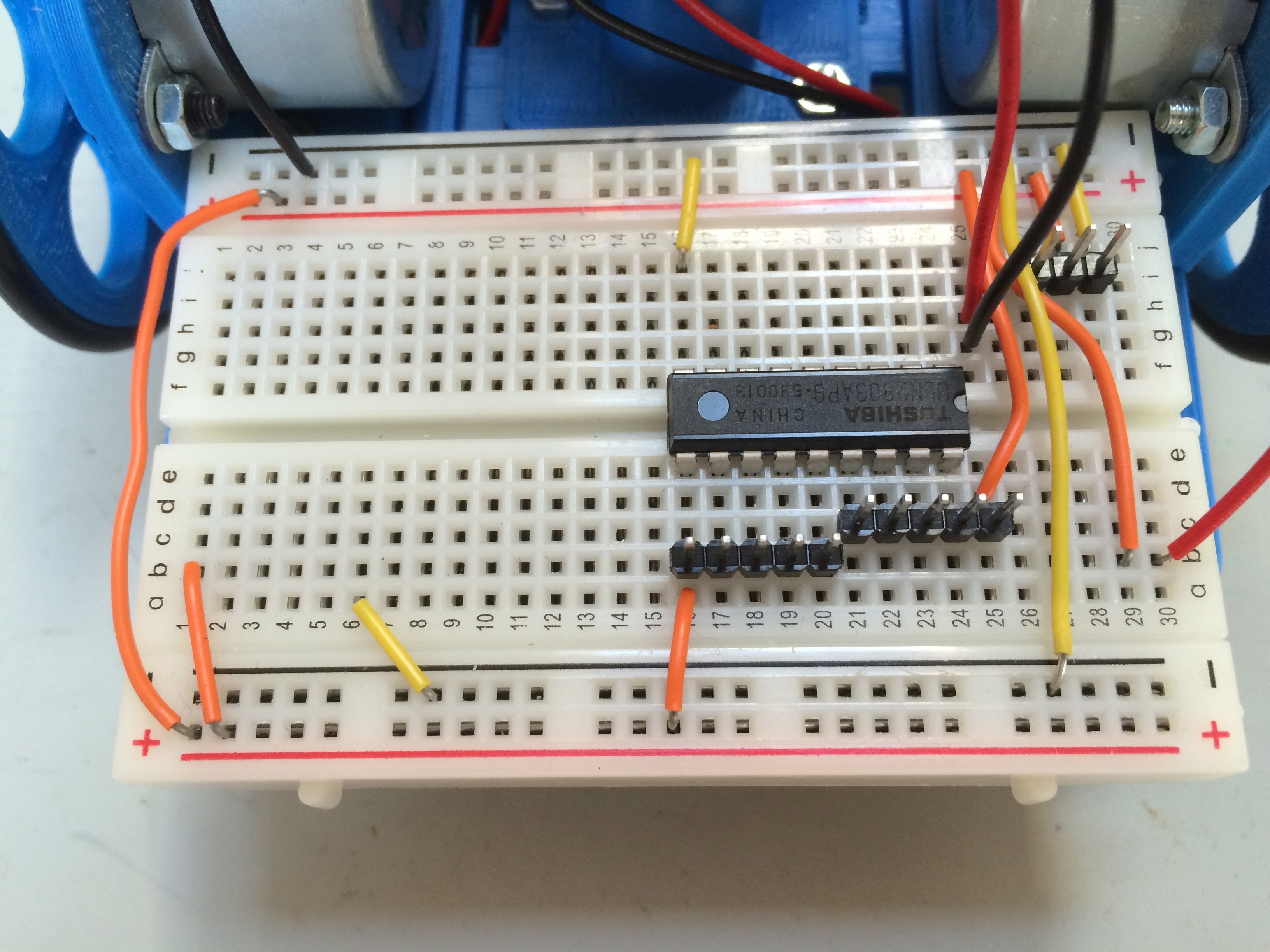

Carefully insert the pins for the

darlington driver, bridging the gap in the breadboard. The notch on the

darlington driver should face the right of the breadboard. The pins go

in holes e16-24 and holes f16-24.

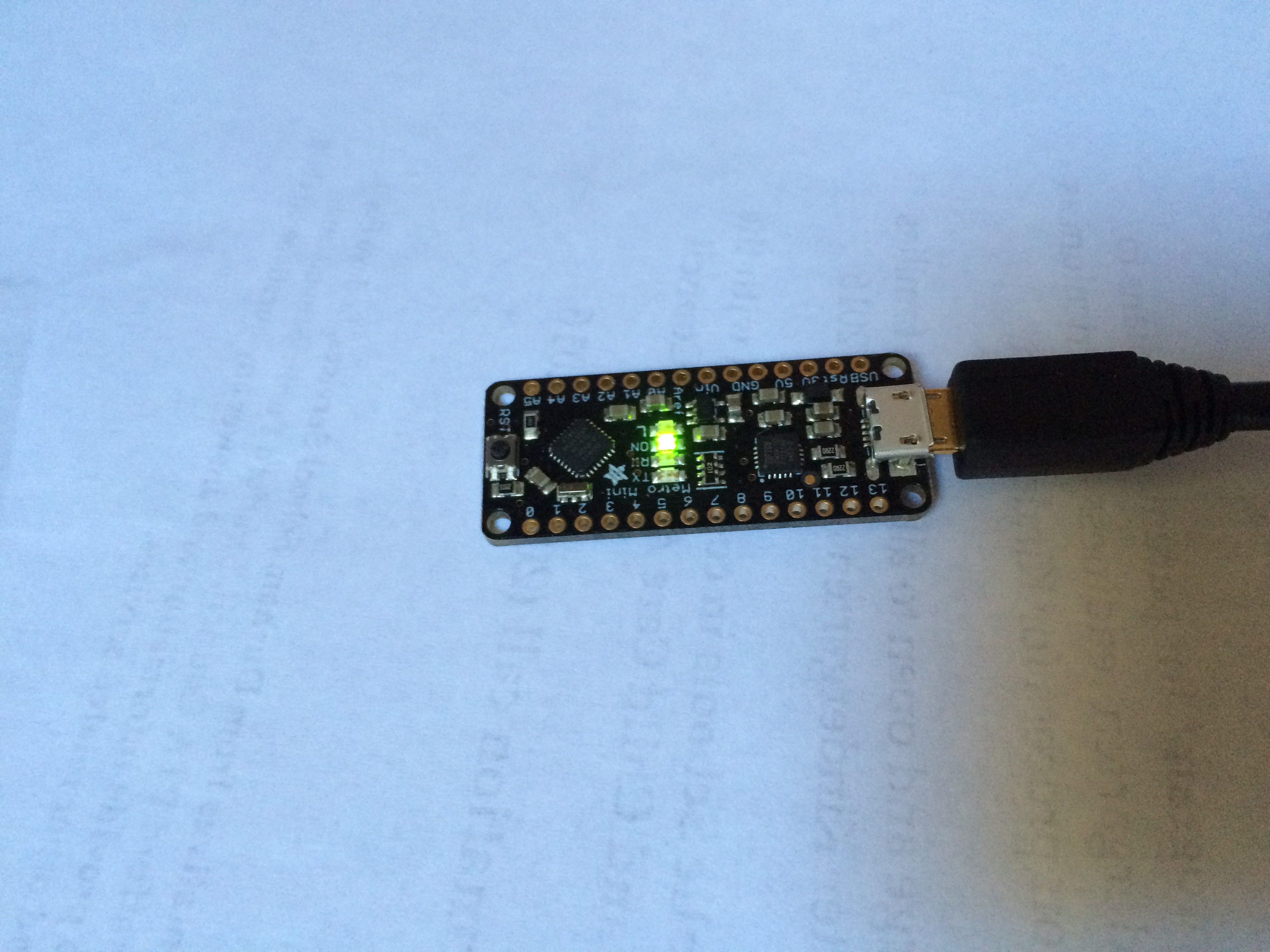

Before you solder the header pins,

load LogoTurtle onto the Metro Mini.

Install the FTDI VCP drivers as well as the SiLabs CP210x drivers from SiLabs.

Download the latest version of LogoTurtle.

Connect the Metro Mini to the Mini

USB cable. Connect the USB cable to your Mac or PC.

Open the Assembler.jar in the

logovm folder.

Click the ASM button. The console

will report back a number of words.

Click Download. The console will

report how long it took and produce a string of hexadecimal numbers and

letters.

Success should report written in 1 second with the hex string: 0000 - 940C 0034 940C 3F00 940C 3F00 940C 3F00.

Failure takes 8 seconds and the hex string will be something like: 0000 – FFFF FFFF FFFF FFFF FFFF FFFF FFFF FFFF.

Quit the Assembler.

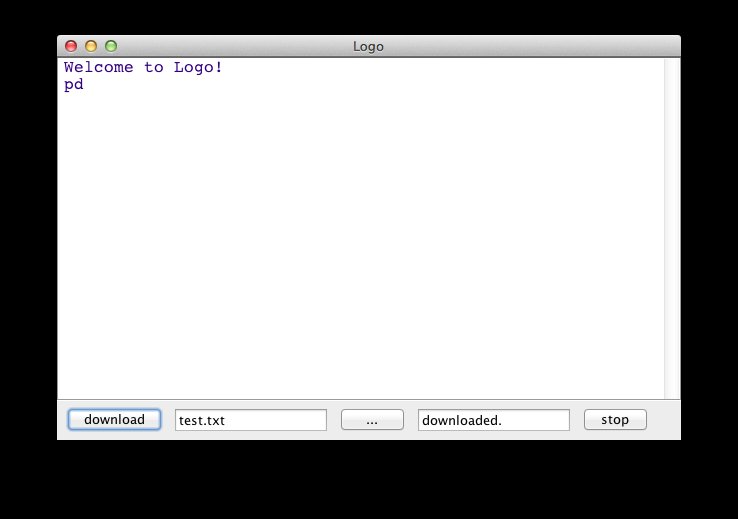

Open Logo.jar in the logo folder.

Click the Download button. After

the console reports Downloaded, type the following in the console (the italics are what LogoTurtle should respond):

print 42

42

print 4 + 5

9

Quit Logo.jar.

Unplug the Metro Mini from the USB

cable.

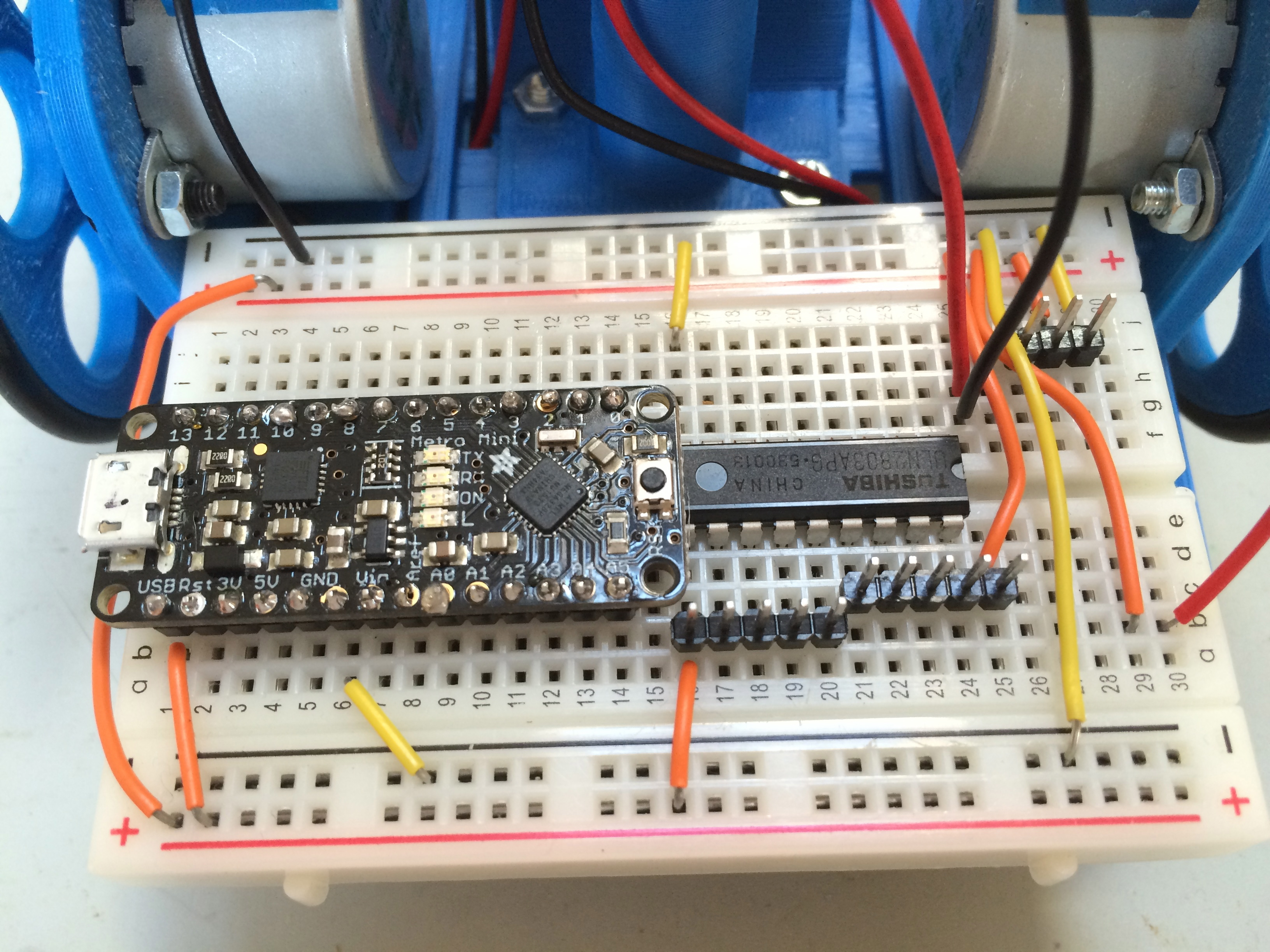

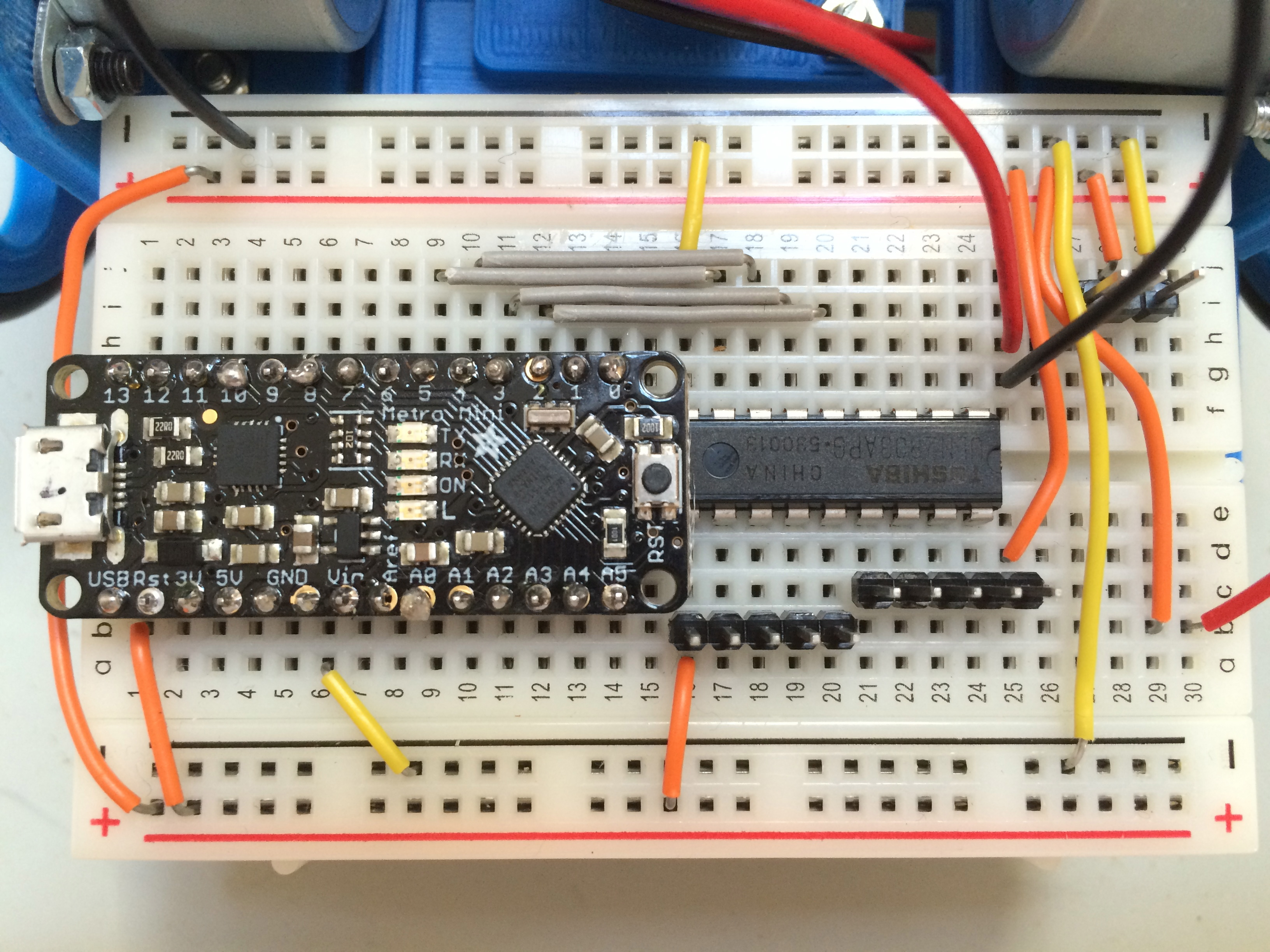

Solder the header pins to the Metro

Mini.

Carefully insert the header pins

from the Metro Mini, bridging the gap in the breadboard. The pins

closest to the front of the breadboard start in hole c1 and continue to

c14. The pins on the far end of the breadboard start in hole g1 and

continue to g14.

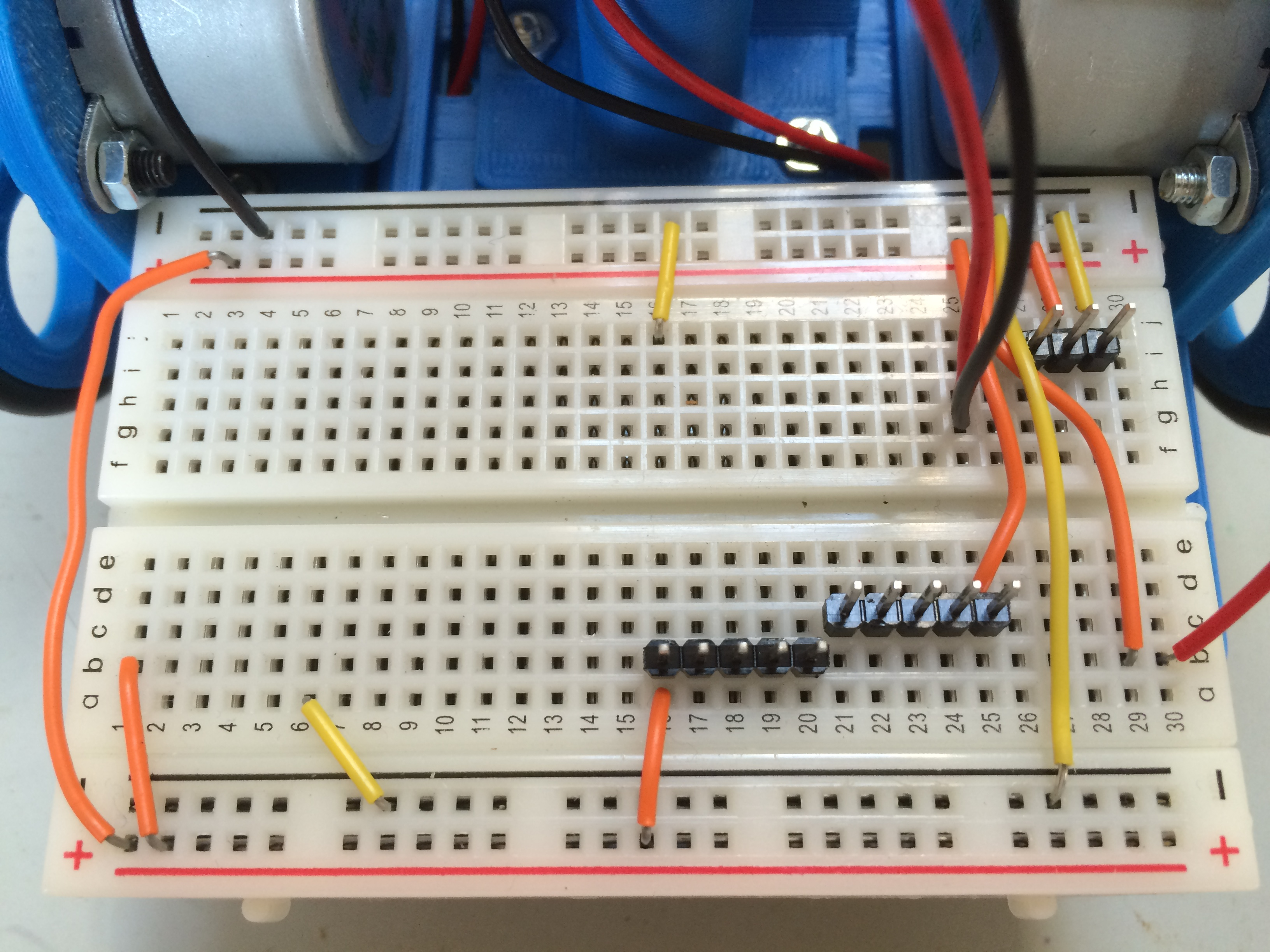

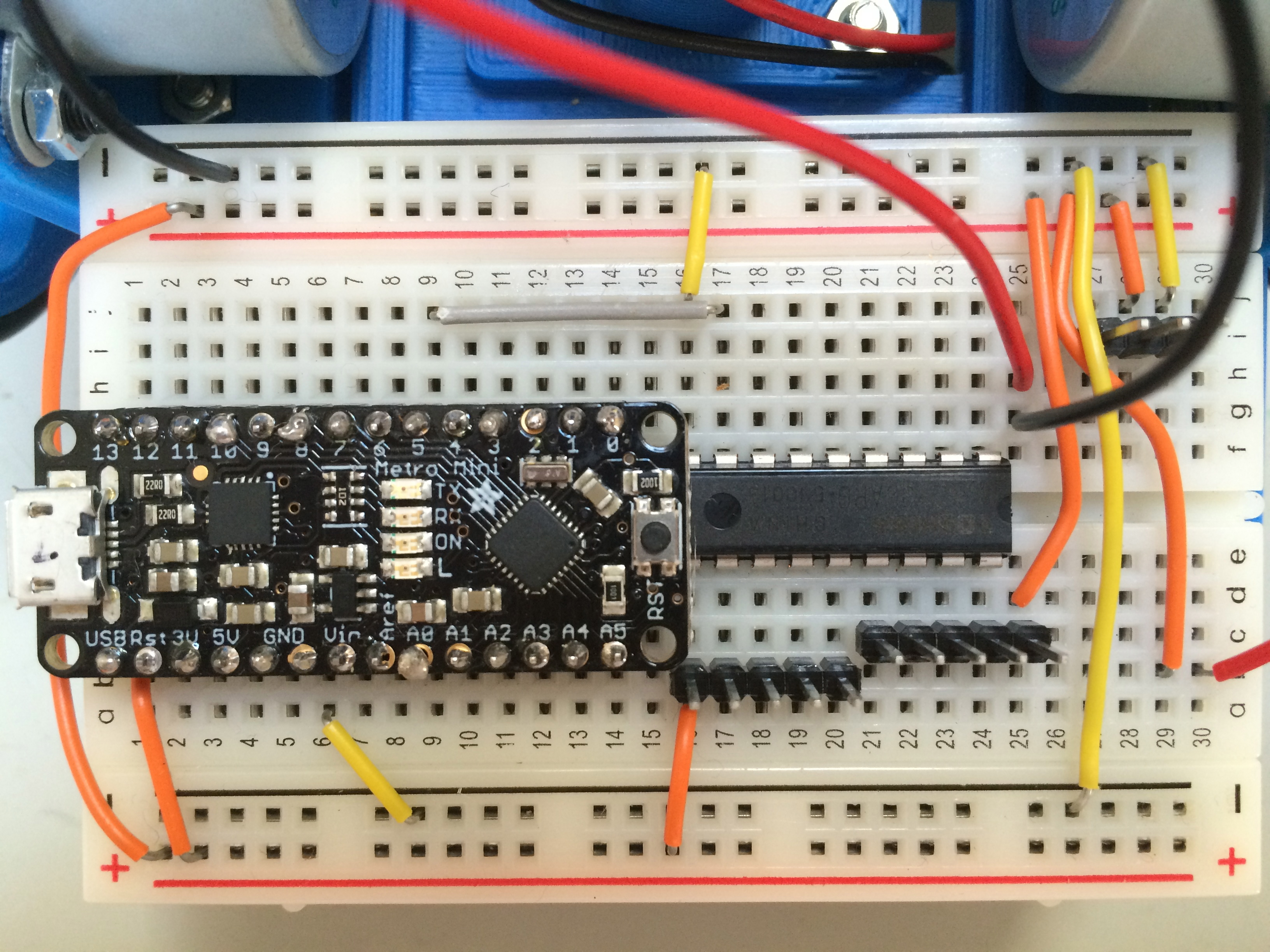

Choose one color jumper wire for

the left stepper motor wiring. I chose gray.

Connect a jumper wire from hole j9

on the breadboard to hole j17. This connects pin 5 on the Metro Mini to

pin 8 on the darlington driver.

Connect a jumper wire from hole j10

on the breadboard to hole j18. This connects pin 4 on the Metro Mini to

pin 7 on the darlington driver.

Connect a jumper wire from hole i11

on the breadboard to hole i19. This connects pin 3 on the Metro Mini to

pin 6 on the darlington driver.

Connect a jumper wire from hole i12

on the breadboard to hole i20. This connects pin 2 on the Metro Mini to

pin 5 on the darlington driver.

You have completed wiring the left

stepper motor array.

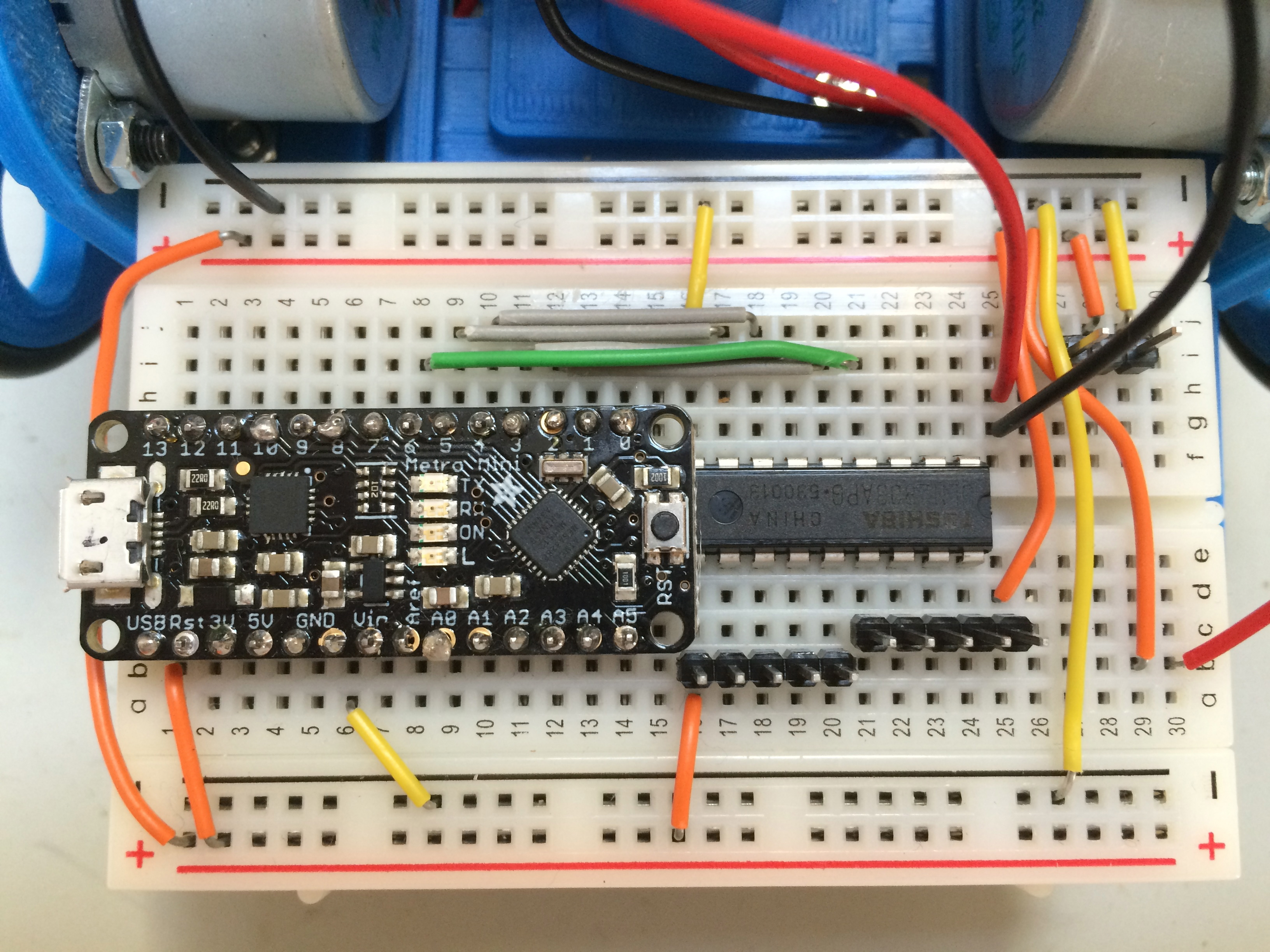

Choose a different color jumper

wire for the right stepper motor wiring. I chose green.

Connect a jumper wire from hole i8

on the breadboard to hole i21. This connects pin 6 on the Metro Mini to

pin 4 on the darlington driver.

Connect a jumper wire from hole i7

on the breadboard to hole i22. This connects pin 7 on the Metro Mini to

pin 3 on the darlington driver.

Connect a jumper wire from hole j6

on the breadboard to hole j23. This connects pin 8 on the Metro Mini to

pin 2 on the darlington driver.

Connect a jumper wire from hole j5

on the breadboard to hole j24. This connects pin 9 on the Metro Mini to

pin 1 on the darlington driver.

You have completed wiring the left

stepper motor array.

Connect a jumper wire from hole h4

to hole j27. This connects pin 10 on the Metro Mini to the servo array.

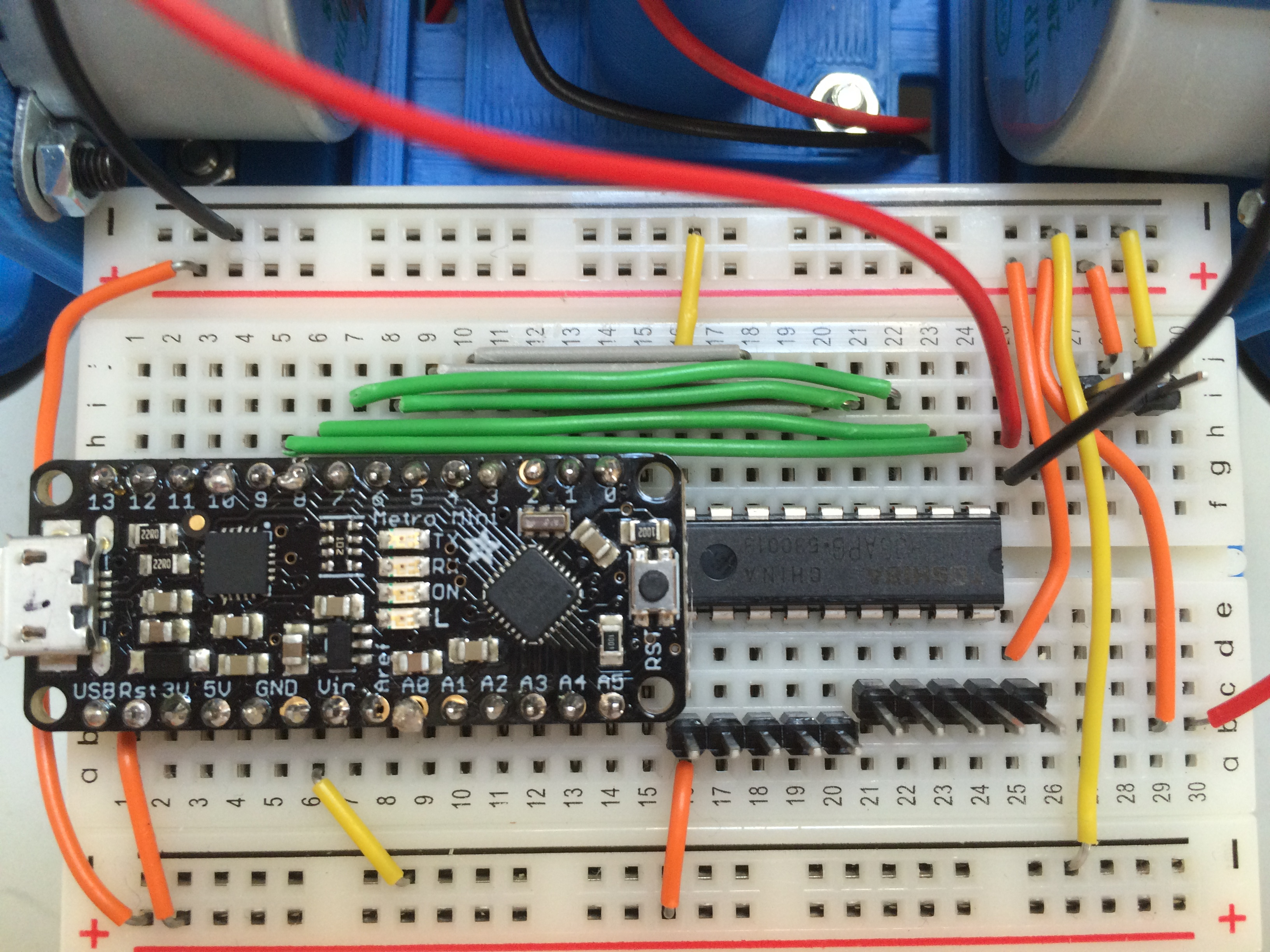

Connect the wires from the left

stepper motor to the left header pins on the breadboard. Make sure the

red wire matches the jumper wire on hole a16. Connect the wires from

the right stepper motor to the right header pins on the breadboard. Make sure the red wire on the stepper

motor matches the jumper wire from the far positive rail to hole d25.

Insert the leads from a 10k

resistor in holes b4 and b6 on the breadboard.

The power stays "on" for some time

after you pull the USB plug. When the power to the Metro Mini gets

restored it looks to the Arduino more like a reset than a power up. By

adding a 10k resistor between the 5V pin of the Arduino and GND,

residual power is drained from the Metro Mini.

Insert a 10k resistor from hole 8

on the near negative rail to hole b9 on the breadboard.

Insert one lead of the photo cell

into hole 5 of the near positive rail. Insert the other lead into hole

a9 on the breadboard.

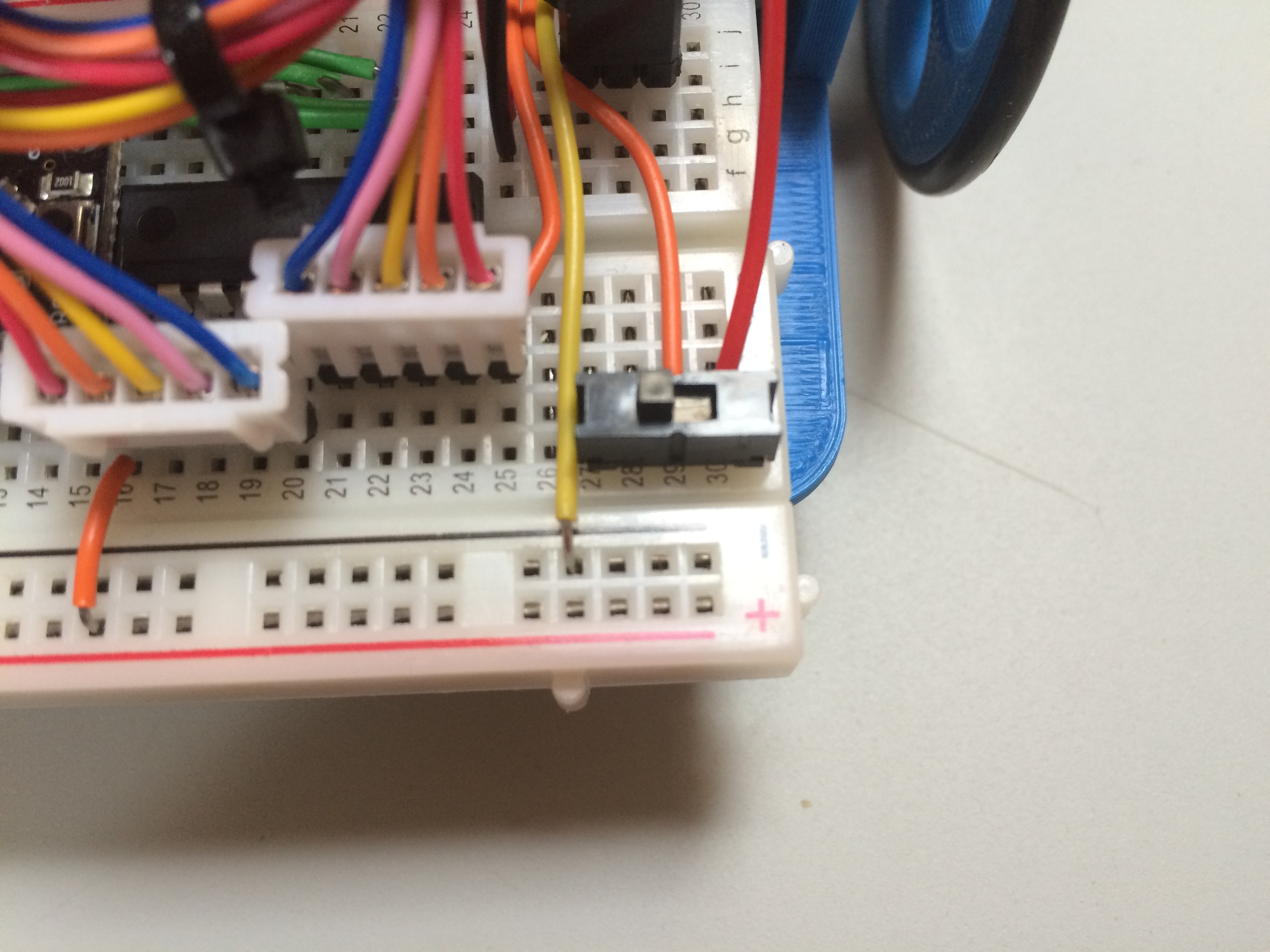

Insert the SPDT power switch into

holes a28-30 on the breadboard.

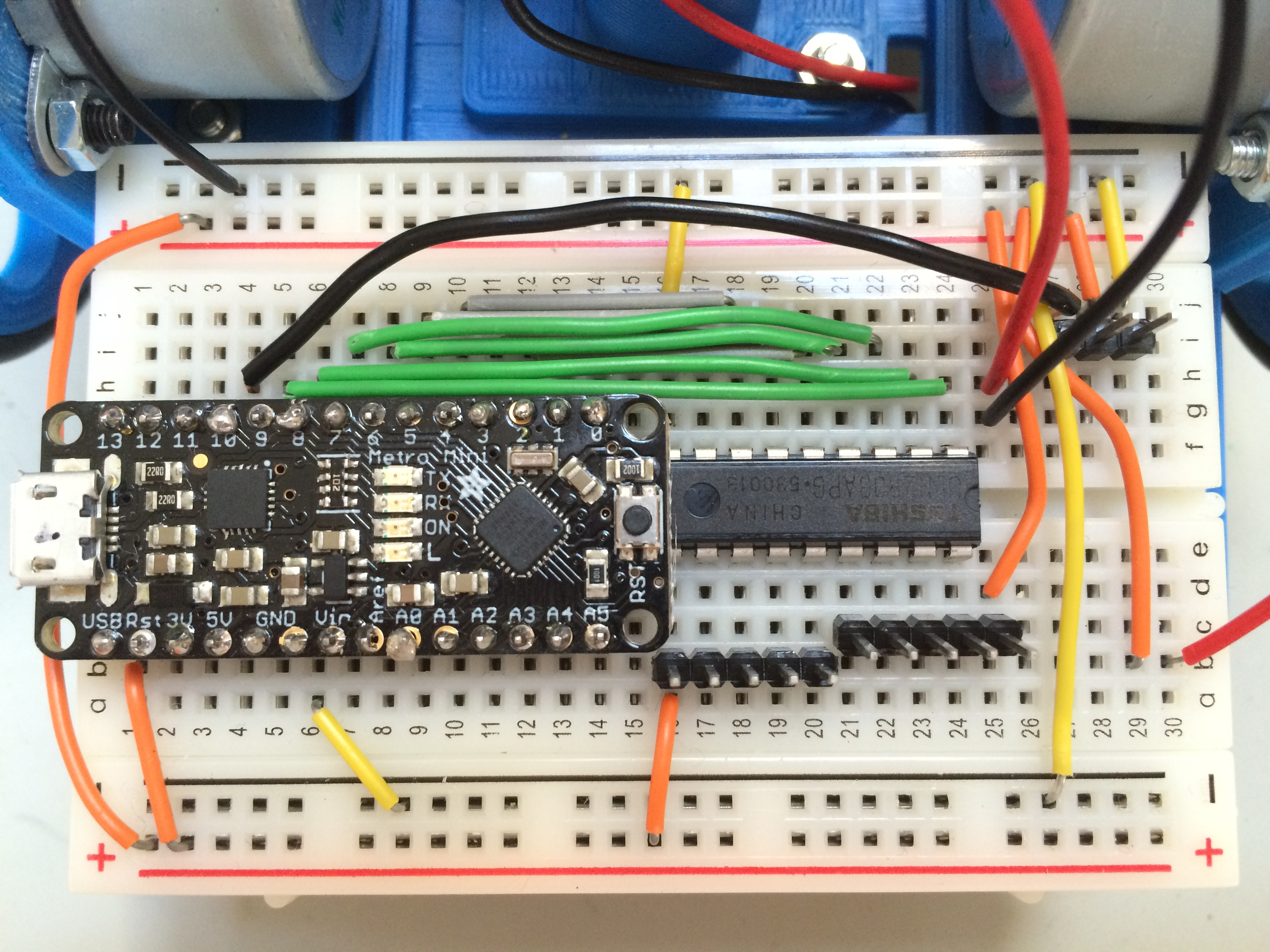

Reattach the 3D printed pen

tube/servo bracket.

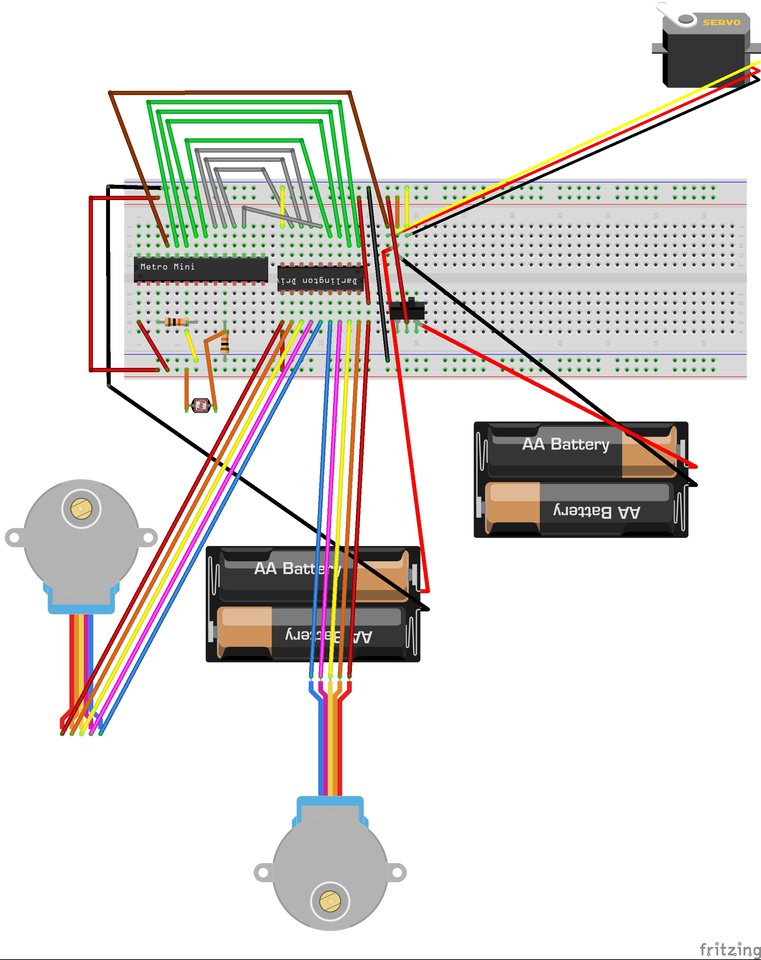

Using the Fritzing diagram below to

double-check all your wiring.

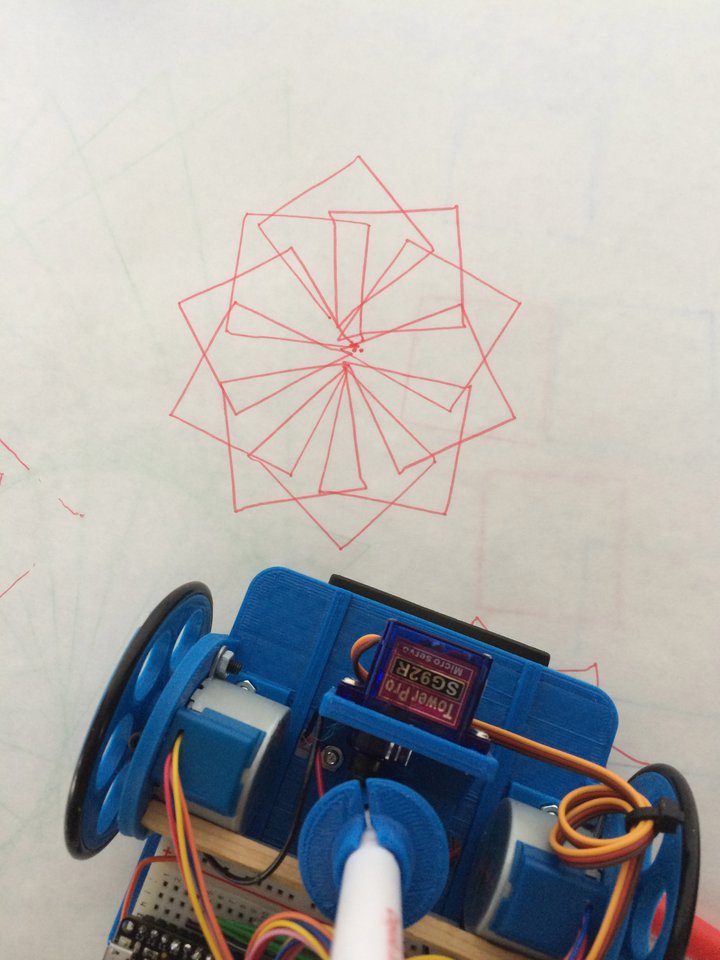

Congratulations! Your LogoTurtle is

constructed!

Next you will calibrate the turtle

to make sure it is working properly.

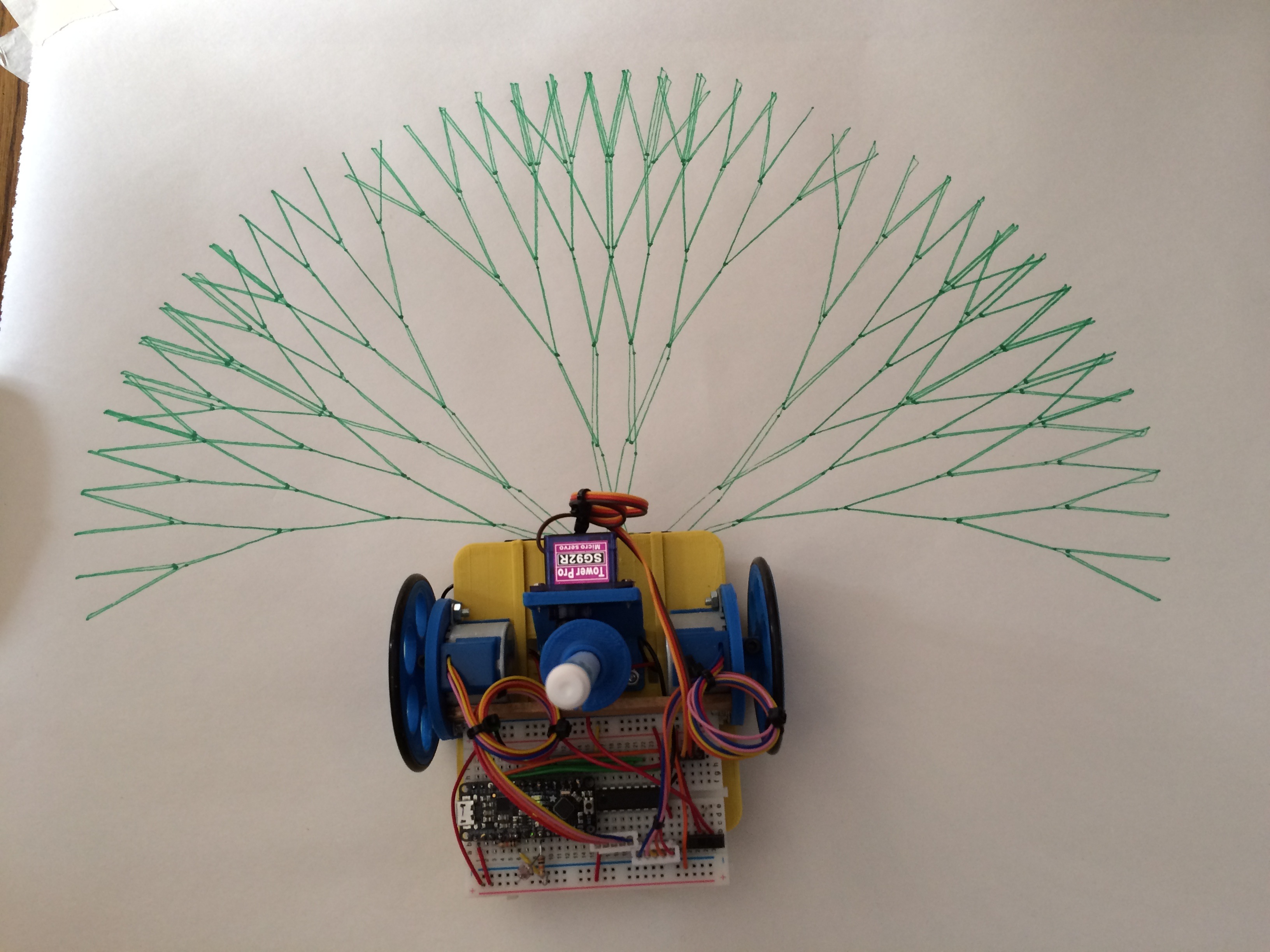

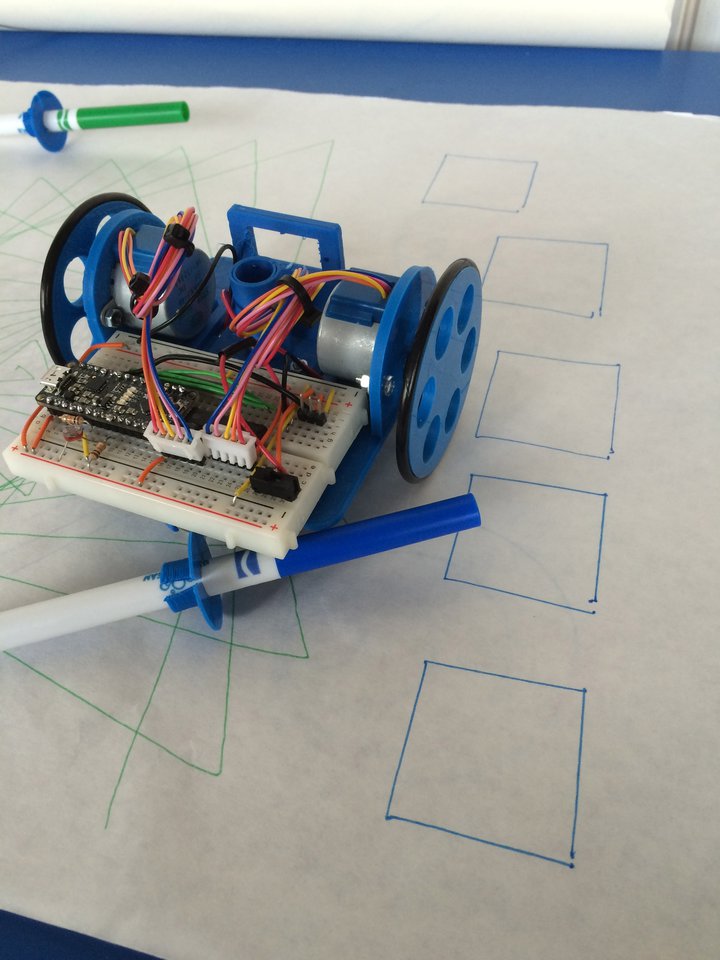

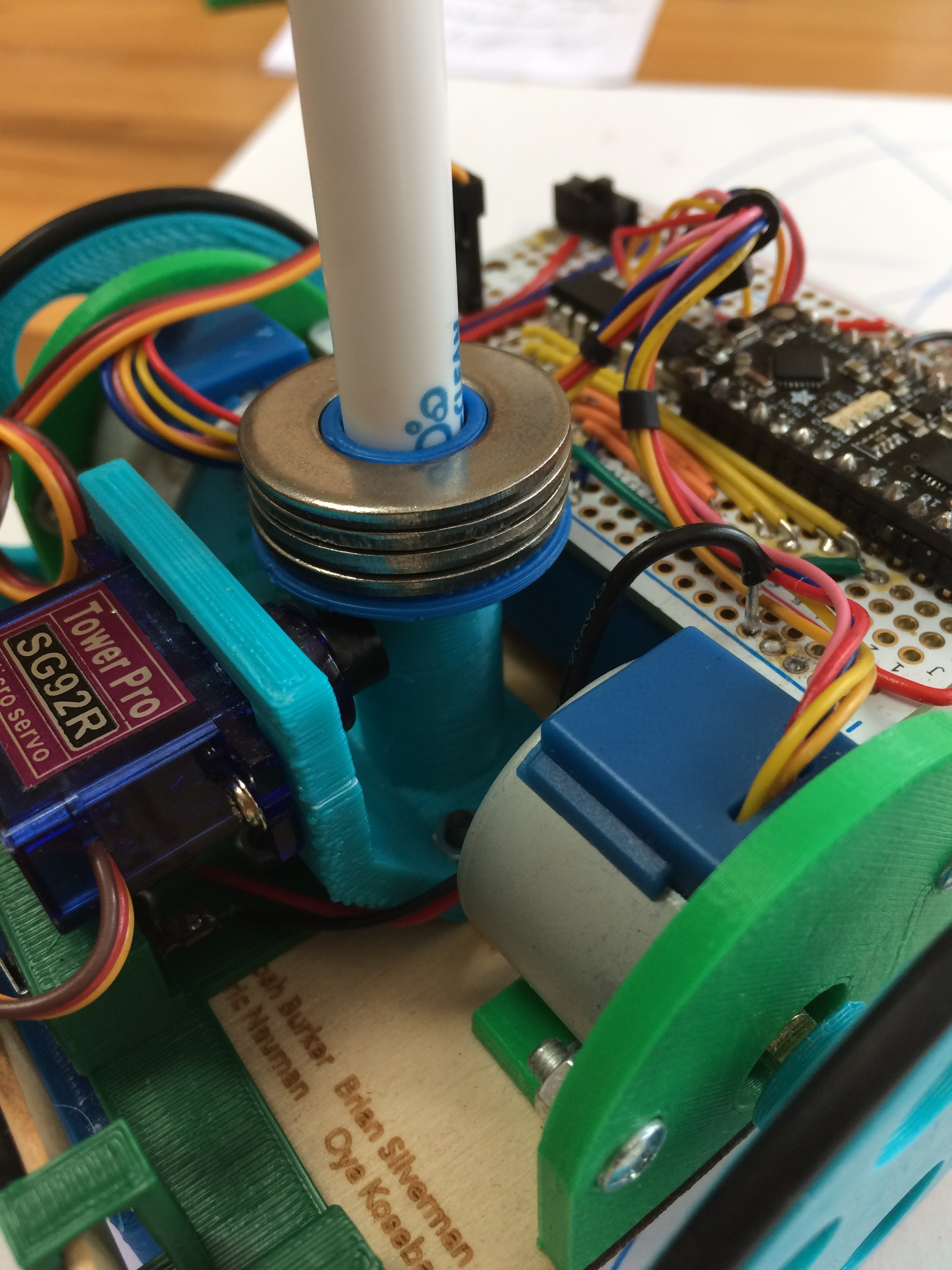

Place a pen in the 3D printed pen

collar. Make sure the the pen is in contact with the paper below the

turtle.

Switch the power switch on.

Press the reset button on the Metro

Mini. The turtle will draw a square. It should have angles close to 90

degrees and the lines should meet.

If the square is skewed or not

quite square, adjust the wheel base by moving the wheels in or out on

the stepper motors. Set on a ruler, a well-calibrated turtle should

have a wheel base of 112mm. Use a heat gun to warm the wheel hub if it

is too snug to fit on the stepper motor.

If the turtle appears not to be

making full 90 degree turns, you might need to place a shim between the

stepper motors. This turtle needed its steppers to be spread slightly

to get the square nearly perfect.

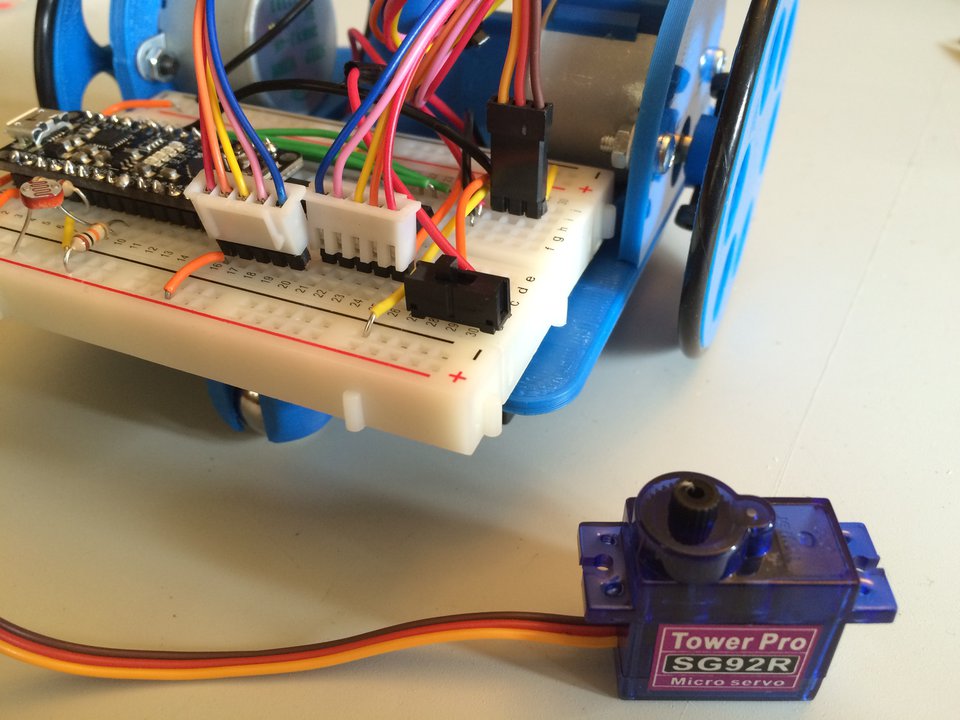

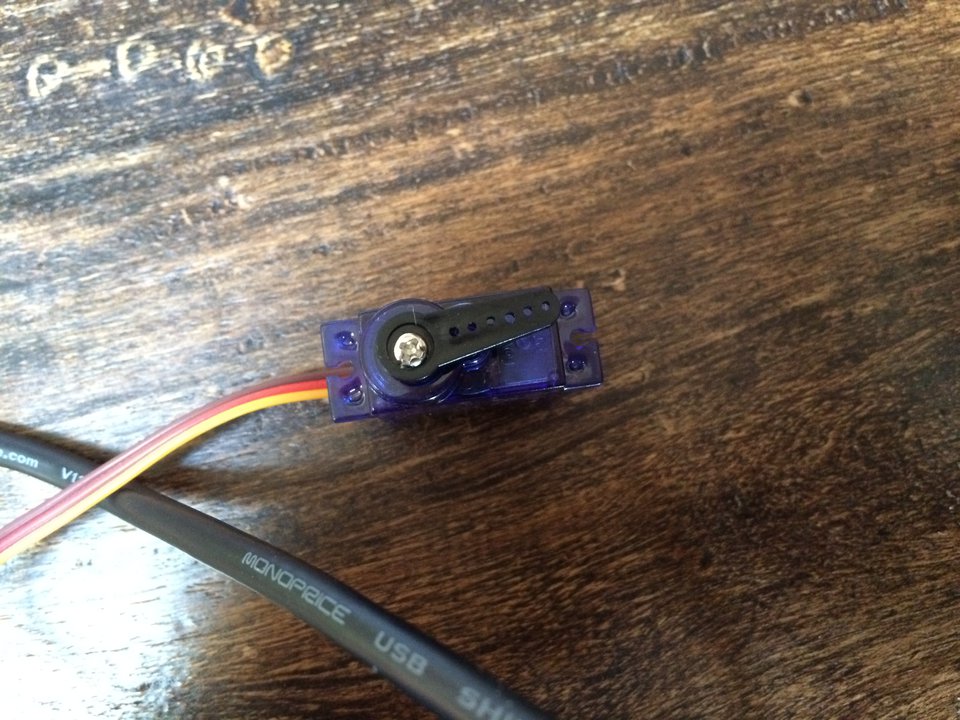

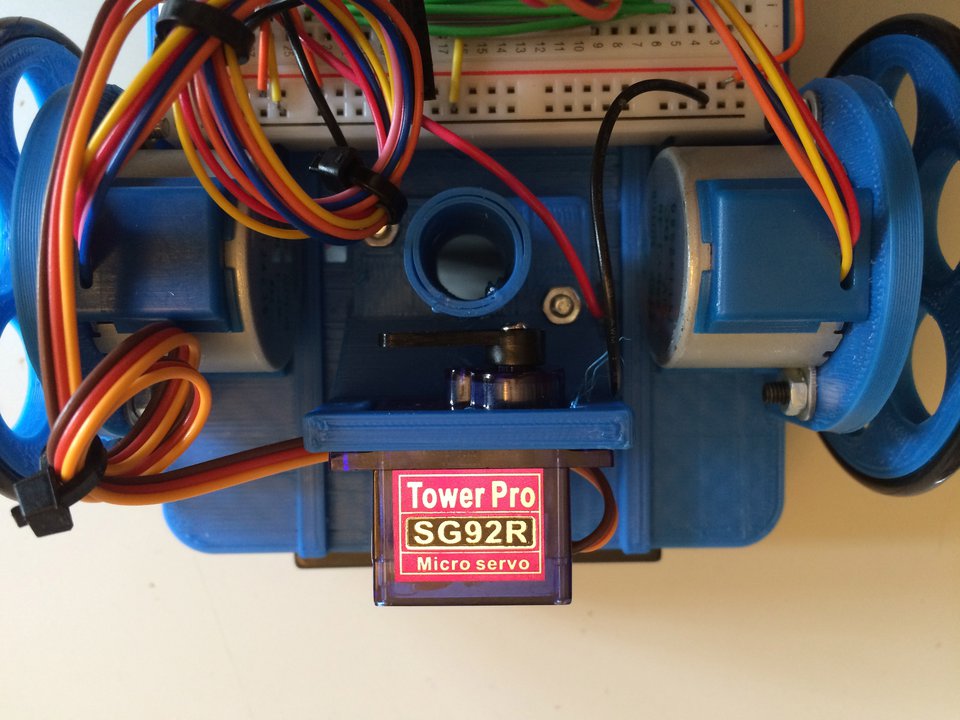

Next, you will add the servo to the

floor turtle so it is able to raise and lower the pen.

Plug the servo into the three

header pins on the breadboard. Be very careful about connecting the

correct pins to the correct servo wires. The rightmost wire on the

breadboard is negative, and the corresponding wire on the servo is

brown colored.

Plug the turtle into the USB cable,

plug the USB cable into the computer, and open Logo.jar. The servo will

move to the down position.

Use the small screw that comes with

the servo to attach the horn to the servo. Mind you do not turn the

servo while you attach the horn.

Snip the support in the middle of

the bracket to remove it. Install the servo in the bracket with two

screws. Make sure the wires come out of the right side of the servo

when it is installed.

Power on the turtle. The servo will

move to the up position.

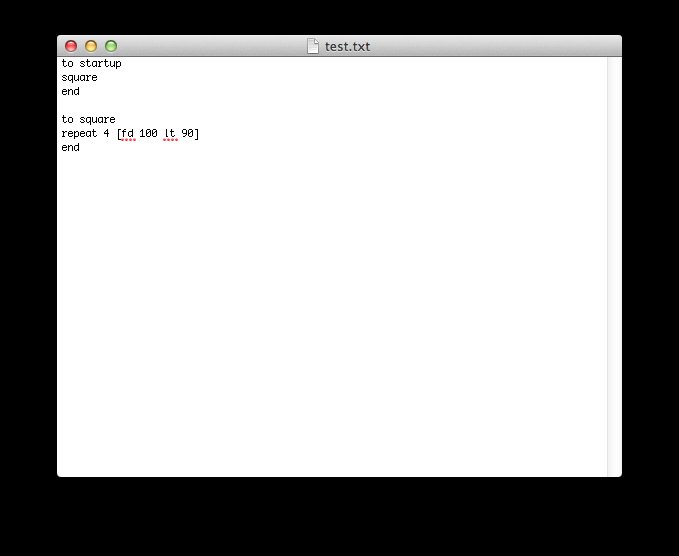

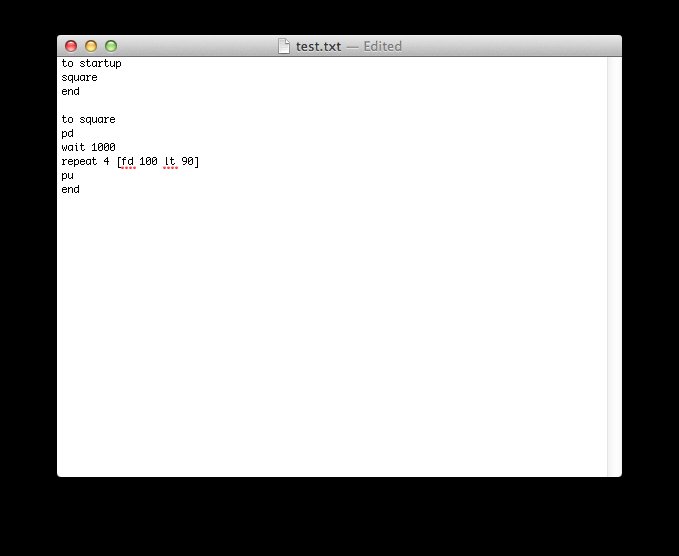

Open the test.txt file in the logo directory with a text

editor.

Add pen commands to the square

procedure. It is a good idea to ask the turtle to wait 1000 after

putting down the pen to make sure the pen is on the paper before the

turtle begins moving.

Connect the turtle to the USB

cable. Click the download button in logo to transfer the updated square

routine.

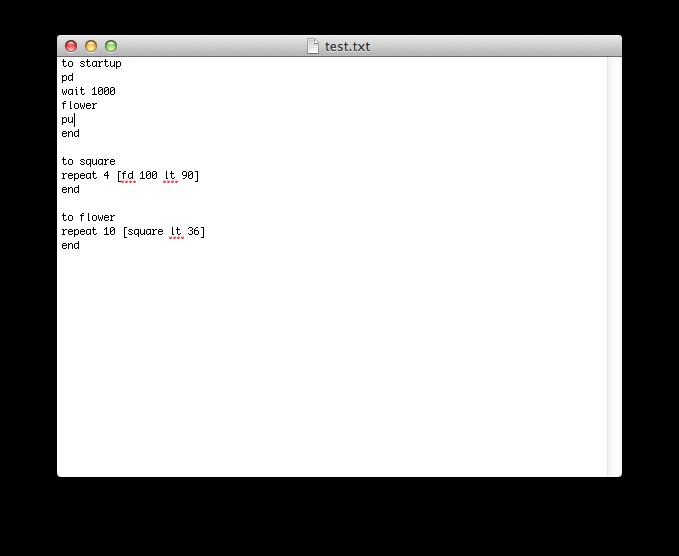

Remix the square procedure and move

the pen commands to the startup procedure. The startup procedure is run

when the reset button is pressed on the Metro Mini.

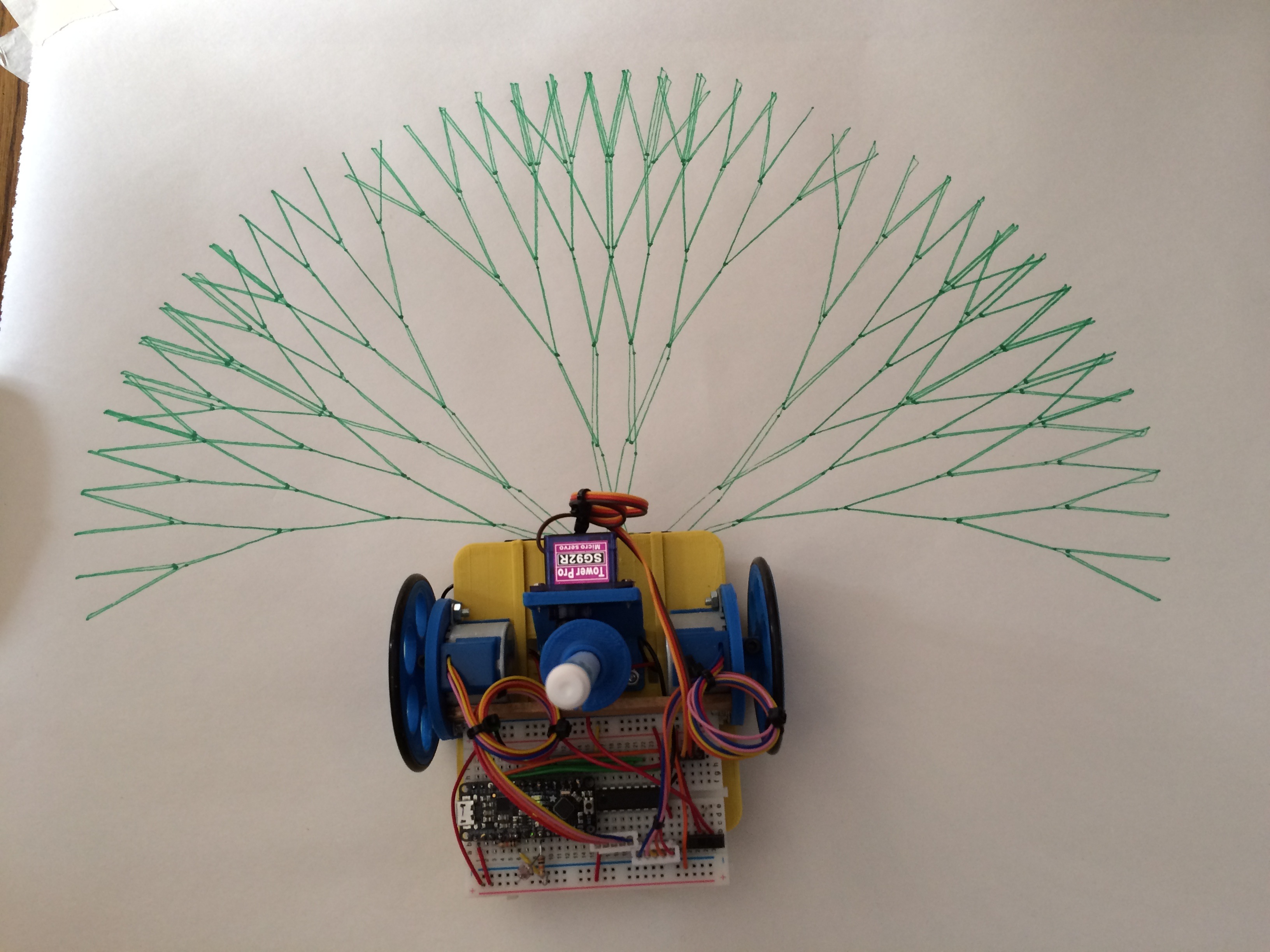

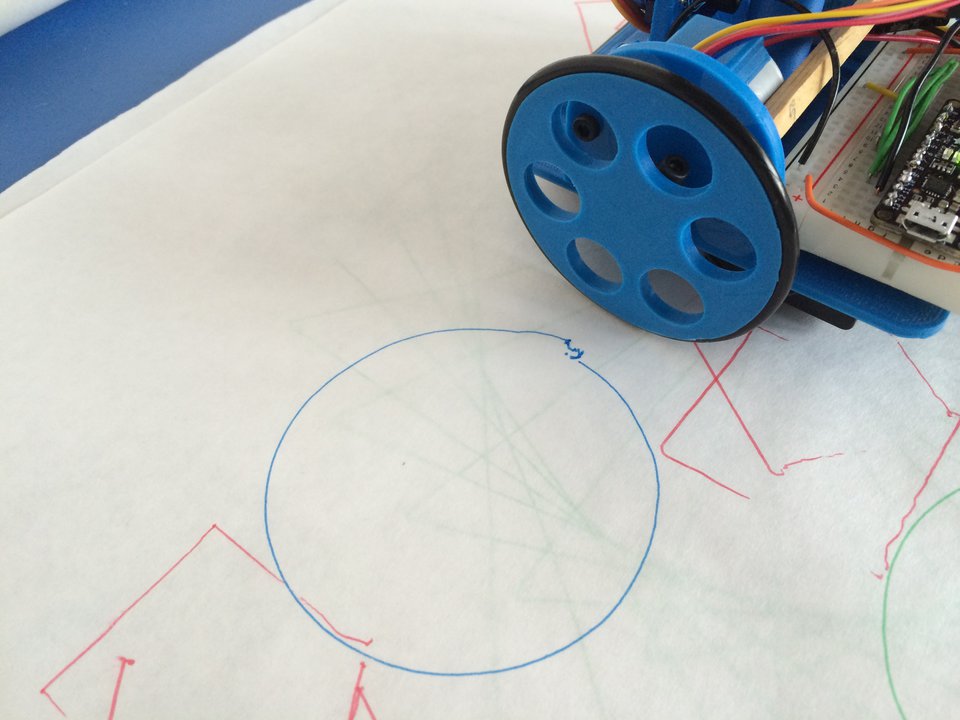

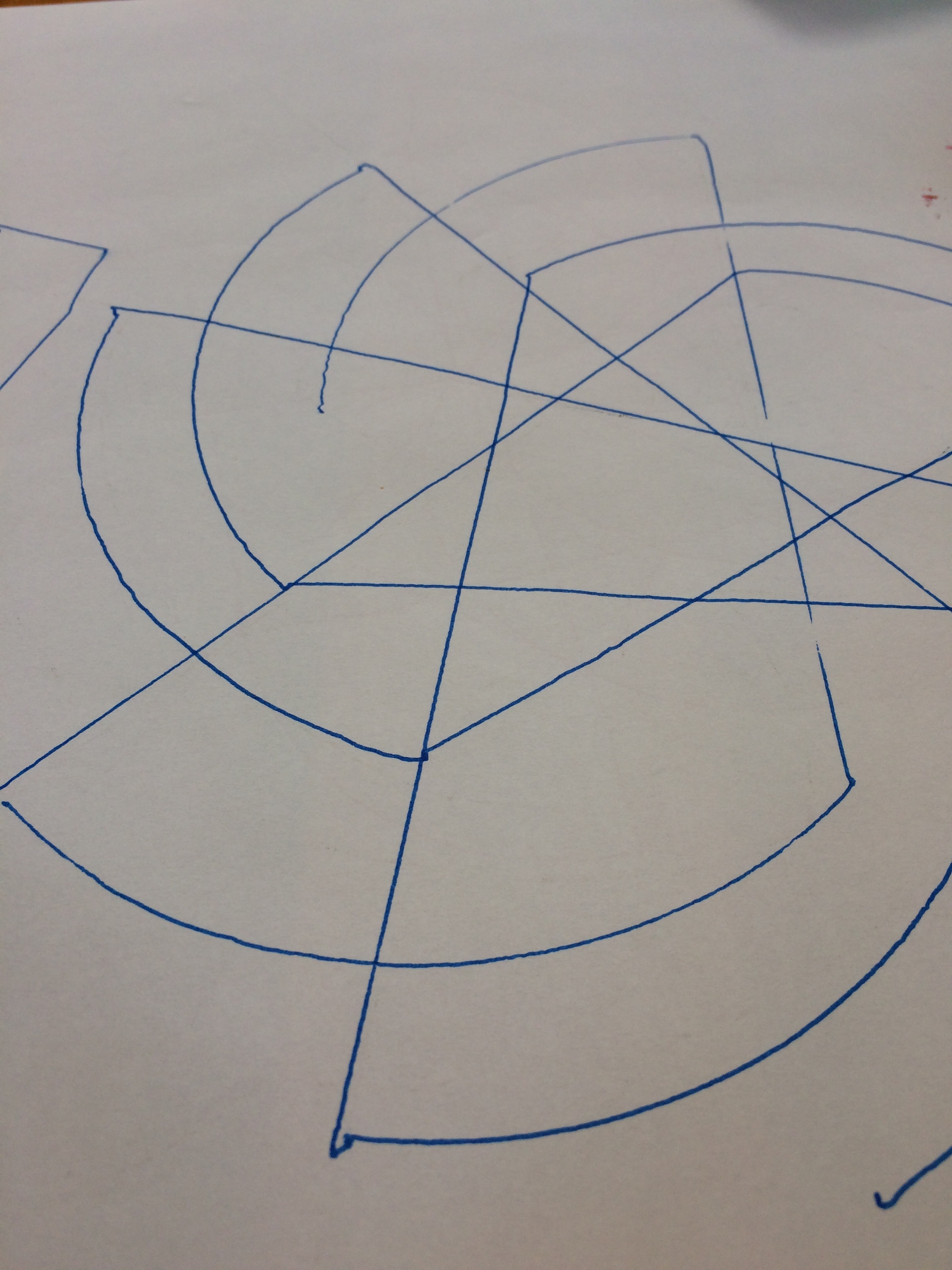

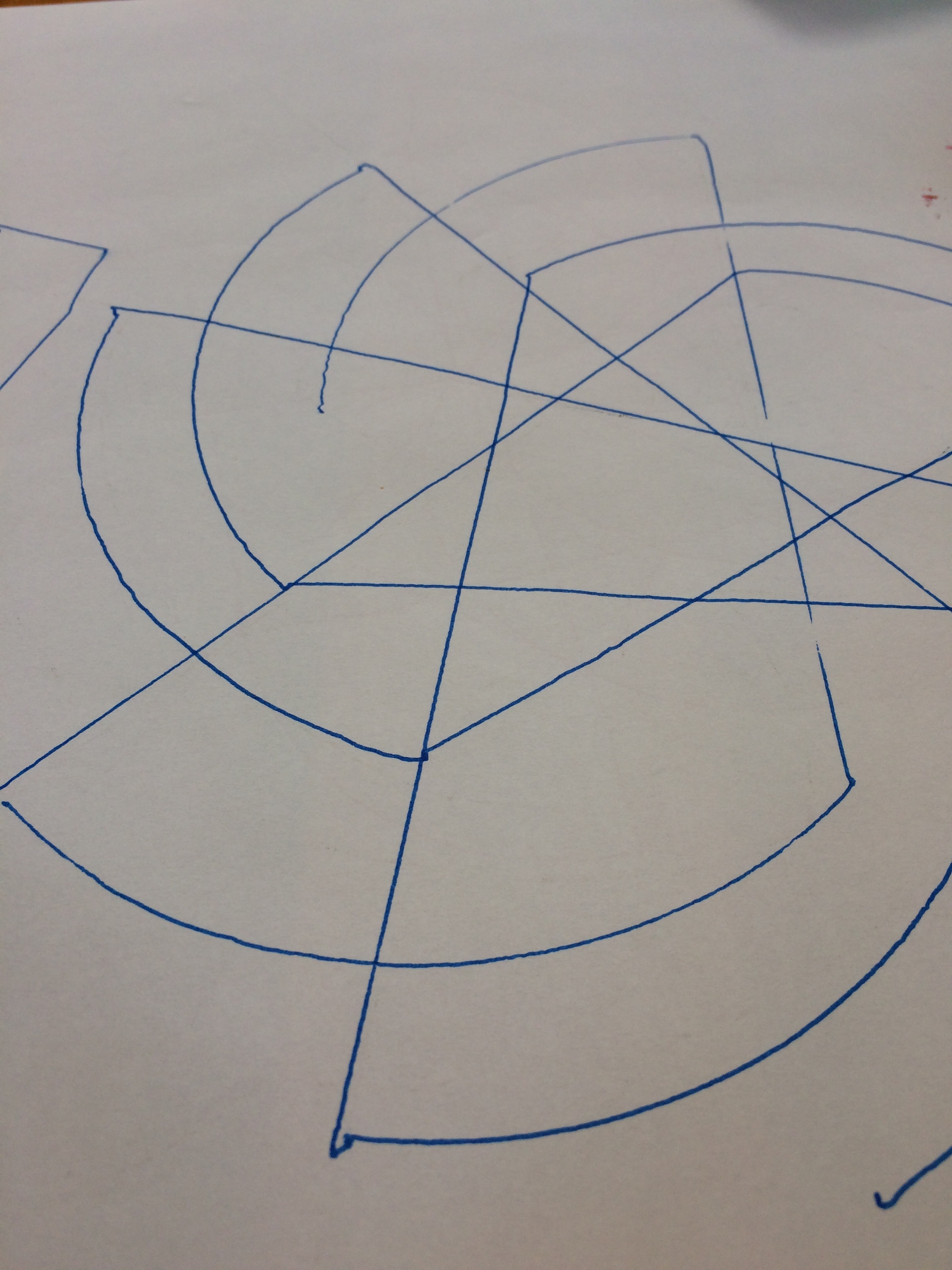

Experiment with the arclt and arcrt commands. The syntax is arclt angle radius. This turtle drew arclt 360 100.

You can take readings from the

photocell sensor. The photocell is plugged into A0 on the Metro Mini,

so print

a0 or repeat 100 [print a0

wait 100] can be interesting

starting points.

to startup

pd wait 1000

let [n a0]

repeat 200 [

arcrt 10 :n

make "n a0

]

pu

alloff

end

Troubleshooting

Double-check all your wiring

against the circuit diagram above.

If LogoTurtle fails to load on the

Metro Mini, load the example Blink sketch from Arduino to confirm your

computer is communicating properly with the Metro Mini.

Make sure that when the servo is in the down position that the pen

holder rests flush on the robot's pen holder. If the pen holder on the

pen is not in contact with the robot the lines will have weird backlash

as the robot changes direction and the lines will not look beautifully

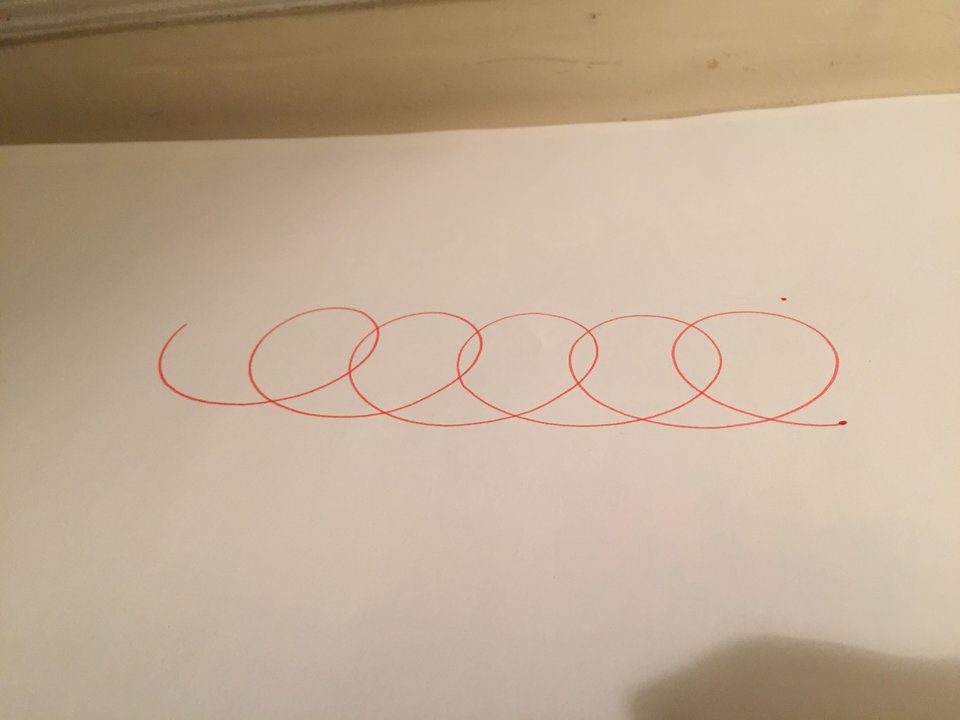

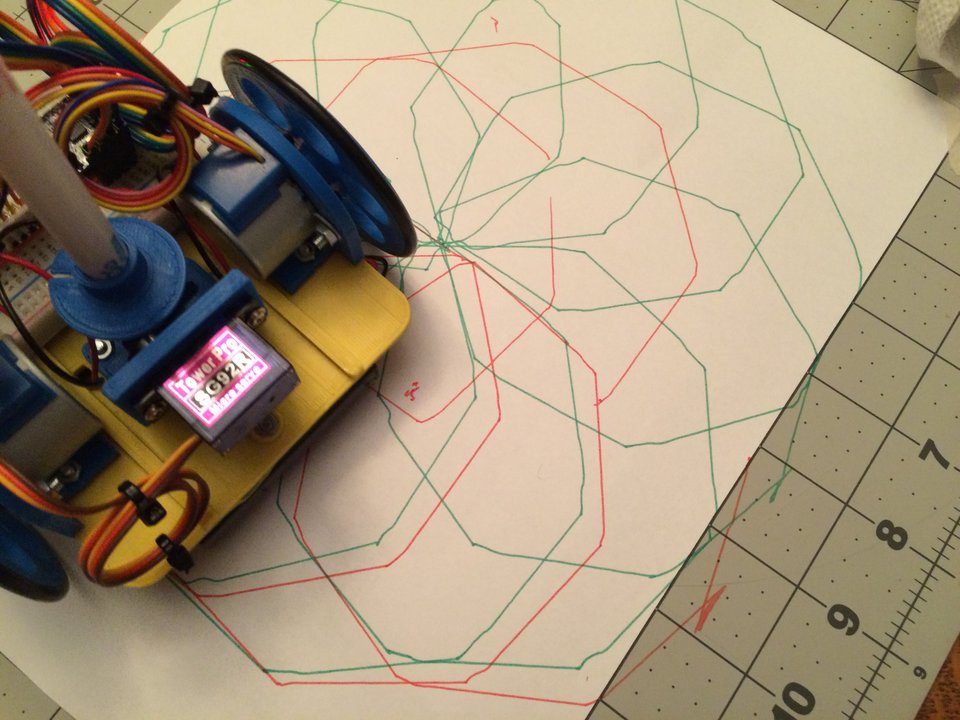

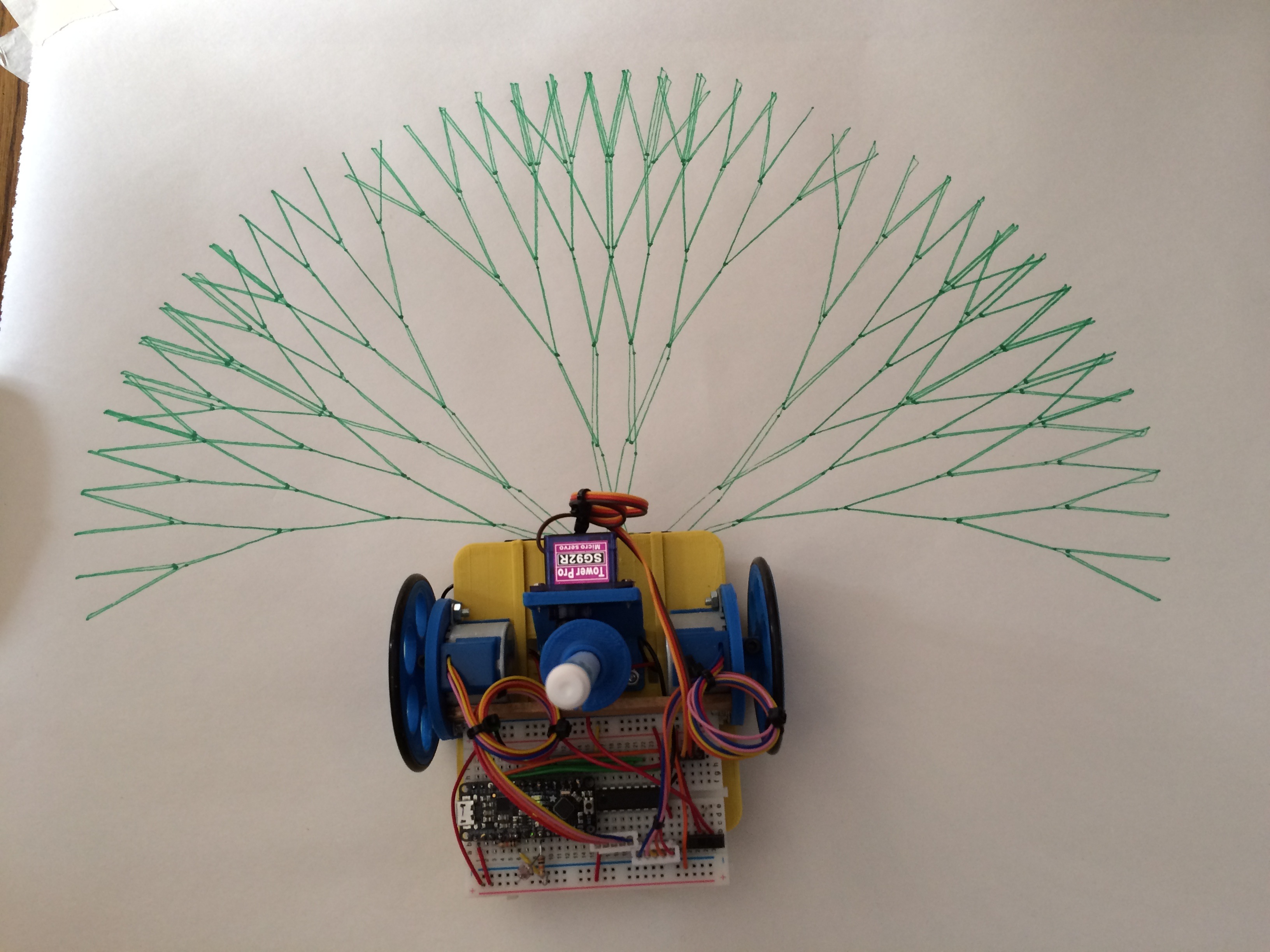

crisp. The green lines in the example below were drawn without contact

with the robot, the red with contact. Notice the line segments after

the 45� turns.

Adding 1/2 inch washers to the pen

holder provides enough weight to the pen that the pen does not shift

after the LogoTurtle changes directions. The result is crisper,

straighter lines and arcs.

Consider joining the LogoTurtle google group.

Thank you to Brian Silverman and Erik Nauman for helping this dream come true.

Thank you to Michael Tempel for an extra set of eyes on the documentation.

This work and images copyright 2017 Josh Burker